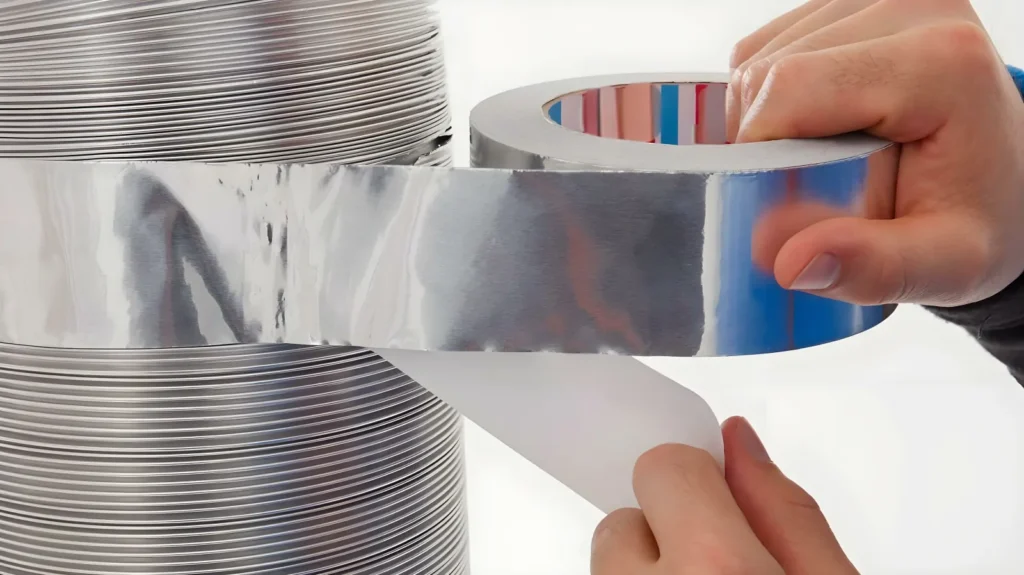

Foil tape is a high-performance adhesive product commonly used in industrial applications, particularly where heat resistance, moisture protection, and electromagnetic interference (EMI) shielding are required. It comes in two primary types of foil tape: pure aluminum foil tape and aluminum foil fiberglass tape.

Pure aluminum foil tape is ideal for applications requiring heat resistance, thermal conductivity, and moisture protection, such as sealing HVAC ducts. It can withstand temperatures ranging from -40°F to 300°F (-40°C to 150°C), making it suitable for most residential and commercial HVAC systems.

Lead foil tapes, which are another type of foil tape, are used for applications that require shielding from electromagnetic radiation or other environmental factors. Copper foil tape is also commonly used in applications requiring high conductivity and effective EMI shielding.

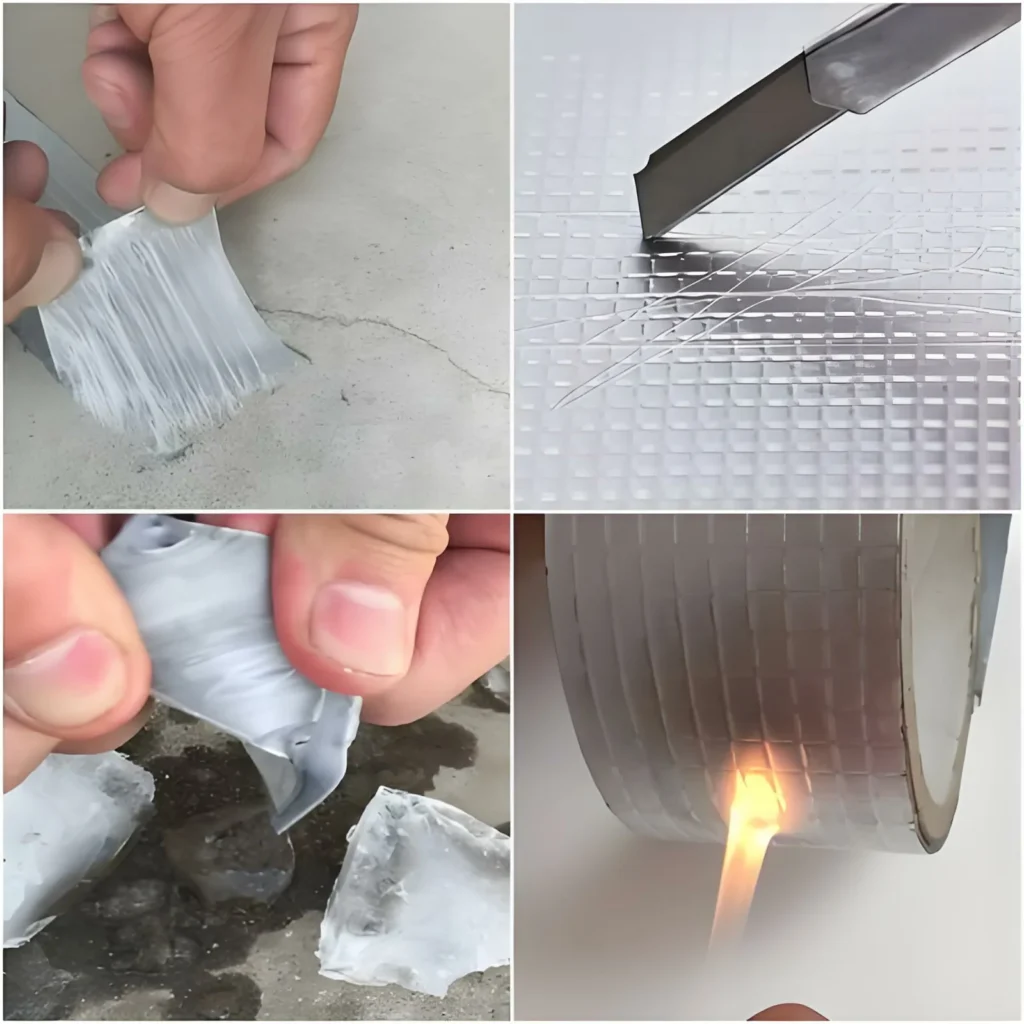

The unique characteristics of metal foil tape, including its superior heat conductivity and adhesive strength, allow it to form a durable bond that lasts over time, even under high temperatures or challenging environmental conditions. The fiberglass reinforcement further increases its durability, making it a preferred choice in environments where mechanical stress, abrasion, and harsh chemicals are present.

| Feature | Pure Aluminum Foil Tape | Aluminum Foil Fiberglass Tape |

| Material | Aluminum | Aluminum + Fiberglass |

| Temperature Range | -40°F to 300°F (-40°C to 150°C) | -40°F to 500°F (-40°C to 260°C) |

| Adhesive Type | Acrylic adhesive | Acrylic adhesive |

| Thickness | 2 mil (0.05mm) to 5 mil (0.13mm) | 4 mil (0.1mm) to 8 mil (0.2mm) |

| Width | 1 inch (25mm) to 4 inches (100mm) | 1 inch (25mm) to 4 inches (100mm) |

| Durability | UV, moisture, solvent resistant | UV, moisture, solvent resistant, tear-resistant |

| Applications | HVAC sealing, electrical shielding | Automotive heat protection, electrical shielding |

Who Uses Foil Tape?

Foil tape is widely used across various industries where high-performance sealing and protection are crucial.

HVAC systems are prime candidates for the use of aluminum foil tape. HVAC contractors commonly use aluminum foil tape to seal ductwork, preventing air leakage and improving energy efficiency. The adhesive properties of the tape ensure a secure, long-lasting bond, and its ability to withstand high temperatures (up to 300°F / 150°C) guarantees that it remains effective in the heat of residential and commercial HVAC systems.

In automotive manufacturing, aluminum foil fiberglass tape is used extensively for heat shielding in engines and to protect electrical wiring from heat and electromagnetic interference. The reinforced fiberglass structure of wire harness tape makes it highly durable, withstanding temperatures up to 500°F (260°C) and offering increased mechanical strength in the face of harsh under-the-hood environments.

Additionally, electrical industries rely on foil tapes for flame resistant applications, particularly to coat electrical cables and prevent overheating in sensitive equipment. Acrylic adhesive plays a significant role in ensuring the long-lasting adhesion of these tapes, even in harsh chemicals environments.

What is Foil Tape Used For?

Foil tapes are used in a variety of applications that require high durability, heat resistance, and moisture protection. In HVAC systems, aluminum foil tape is primarily used to seal ductwork and insulate pipes and ducts, preventing heat loss and improving energy efficiency. For example, in residential and commercial HVAC systems, aluminum foil tape can ensure tight seals and prevent air leakage, improving overall system efficiency. The tape’s ability to withstand temperatures ranging from -40°F to 300°F (-40°C to 150°C) makes it ideal for sealing HVAC ducts exposed to fluctuating environmental conditions.

In the automotive industry, aluminum foil fiberglass tape is essential for flame retardant applications, such as protecting electrical wiring, fuel lines, and components in close proximity to the engine. It is also used in wire insulation, preventing thermal damage and reducing the risk of short circuits due to heat. With its temperature resistance of up to 500°F (260°C), aluminum foil fiberglass tape provides a reliable solution for heat-sensitive automotive components.

Electrical industries use aluminum foil tape extensively for EMI shielding. The metal foil provides an effective barrier to EMI, ensuring that electronic equipment operates without disruption. The tape’s temperature resistance ensures that it can be used in environments where temperatures range from -40°F to 300°F (-40°C to 150°C), providing long-lasting protection for critical components. Additionally, foil tapes offer superior sealing and insulation properties, which make them invaluable for protecting sensitive equipment in industrial settings.

In construction, foil tapes offer an efficient way to seal and insulate joints and seams in insulation materials, ensuring that they are protected from moisture and extreme temperatures. This prevents the insulation from losing its effectiveness and helps maintain energy efficiency in buildings, particularly in harsh weather conditions. The ability of aluminum foil tape to withstand UV radiation and moisture exposure ensures that it remains functional for extended periods.

When Should You Use Foil Tape?

Foil tapes should be used in any application that requires a high-performance, durable seal to protect against heat, moisture, and electromagnetic interference. It is particularly beneficial in environments where temperatures are high or fluctuate significantly, such as HVAC systems, automotive manufacturing, and electrical installations. In HVAC systems, aluminum foil tape is essential when sealing ducts or insulating pipes and ducts. Aluminum foil tape is highly effective in preventing air leaks and improving energy efficiency in both residential and commercial HVAC systems.

In automotive and industrial environments, where high temperatures and mechanical stress are common, aluminum foil fiberglass tape is the preferred option. It can withstand temperatures up to 500°F (260°C) and provides additional durability due to the fiberglass reinforcement. In electrical systems, foil tapes are crucial when protecting sensitive components from EMI, ensuring that electrical systems perform reliably even in environments with high levels of interference.

Additionally, foil tapes offer an ideal solution when seal and insulate insulation materials in construction and industrial applications. The tape’s ability to withstand moisture, UV exposure, and extreme temperatures ensures that it will remain effective in a variety of applications, from sealing insulation in homes to protecting industrial equipment.

Where is Foil Tape Applied?

Foil tape is used across a variety of industries, including HVAC systems, automotive, electrical, and construction. In HVAC systems, aluminum foil tape is applied to seal ducts and prevent air leakage. This is particularly important in both residential and commercial HVAC systems, where preventing heat loss can significantly improve energy efficiency. The tape is also used to insulate pipes and ducts, ensuring that heat is retained within the system and reducing the overall energy consumption.

In automotive manufacturing, aluminum foil fiberglass tape is used extensively to protect wires, cables, and other components from heat. This is particularly crucial in automotive engines, where temperatures can reach extreme levels, often exceeding 500°F (260°C). The reinforced fiberglass structure of the tape ensures it remains durable even in these harsh conditions.

Electrical industries use foil tapes to shield wires, cables, and components from electromagnetic interference (EMI). The metal foil provides an effective barrier to EMI, ensuring that sensitive electronics remain protected from disruptions that could compromise their functionality. In construction, foil tapes are used to seal and insulate joints in insulation materials, protecting them from moisture and ensuring that insulation remains effective in extreme temperatures.

Why is Foil Tape Important?

Foil tape is vital in industries that require effective sealing, insulation, and protection against environmental factors such as heat, moisture, and electromagnetic interference. Its ability to withstand extreme temperatures (ranging from -40°F to 500°F / -40°C to 260°C) and provide long-lasting protection against moisture and UV exposure makes it indispensable in HVAC systems, automotive, electrical, and construction applications.

In HVAC systems, foil tapes offer improved energy efficiency by preventing air leaks and heat loss, ensuring that systems operate at peak performance. In automotive manufacturing, aluminum foil fiberglass tape protects critical components from heat and electromagnetic interference, reducing the risk of equipment failure and extending the lifespan of vehicles. For electrical industries, foil tapes provide essential EMI shielding, ensuring that electronic systems remain operational in high-interference environments.

Foil tapes offer a crucial role in construction, where they are used to seal and insulate insulation materials and protect against moisture and temperature fluctuations. This helps to ensure the long-term performance and energy efficiency of insulation systems, making it an essential material in building projects.

How Does Foil Tape Work?

Foil tape works by utilizing a combination of a metal foil backing (typically aluminum) and a strong acrylic adhesive. The aluminum foil provides excellent heat conductivity, which makes it ideal for applications requiring thermal insulation. The acrylic adhesive bonds securely to surfaces, ensuring that the tape stays in place even under challenging conditions. In aluminum foil fiberglass tape, the addition of fiberglass reinforcement increases the tensile strength, tear resistance, and durability of the tape, making it suitable for high-stress applications where harsh chemicals or mechanical force are involved.

The metal foil also serves as an effective barrier against electromagnetic interference (EMI), ensuring that sensitive components in electrical systems are protected from external interference. The pressure-sensitive acrylic adhesive allows the tape to bond strongly without the need for additional tools or heat, providing a convenient and reliable solution for a wide range of applications.

Foil tapes are an essential material for a wide range of applications, offering superior heat resistance, moisture protection, and EMI shielding. Whether used in HVAC systems, automotive manufacturing, electrical installations, or construction, foil tapes offer a reliable, long-lasting solution that meets the demands of even the most challenging environments. The ability to withstand temperatures ranging from -40°F to 500°F (-40°C to 260°C) ensures its effectiveness in diverse applications, making it an indispensable tool for enhancing system performance, reducing maintenance costs, and ensuring long-term reliability.