Aluminium foil tape, recognized for its exceptional performance, is widely used across industries due to aluminum foil tape’s heat resistance, pressure-sensitive properties, and flexibility. Known by different names like electromagnetic shielding tape in electronics or duct sealing tape in HVAC, this adhesive tape answers the question: what is foil tape used for? From sealing HVAC ducts and shielding electrical cables to protecting pipelines and serving household repairs, its wide range of applications demonstrates its indispensable value.

Aluminum foil tape uses include thermal insulation, electromagnetic shielding, flame resistance, and more. With a temperature resistance range of -20°C to 260°C (-4°F to 500°F), a variety of types of foil tape—such as copper foil tape, lead foil tapes, and fiberglass-reinforced tape—ensure optimal performance in specific industries. Backed by durable adhesives like acrylic adhesive, these tapes maintain secure bonding under extreme weather conditions and ensure reliability across both professional and domestic tasks.

What Is Aluminum Foil Tape?

Aluminum foil tape, often considered a specialized metal foil adhesive tape, is made of aluminum foil backed with pressure-sensitive acrylic adhesive or silicone. What is Foil Tape

Known for being flame retardant, flame resistant, moisture-resistant, and thermally conductive, this versatile material meets key U.S. industry standards, such as ASTM E84 for surface burning characteristics and UL 723 for flame spread and smoke development. It is offered in a wide range of applications. Additionally, it serves as an effective vapor barrier, ensuring optimal performance in challenging weather conditions.

The two primary types of adhesive tapes in this category are pure aluminum foil tape and fiberglass-reinforced aluminum foil tape, each tailored for specific needs.

Aluminum Foil Tape

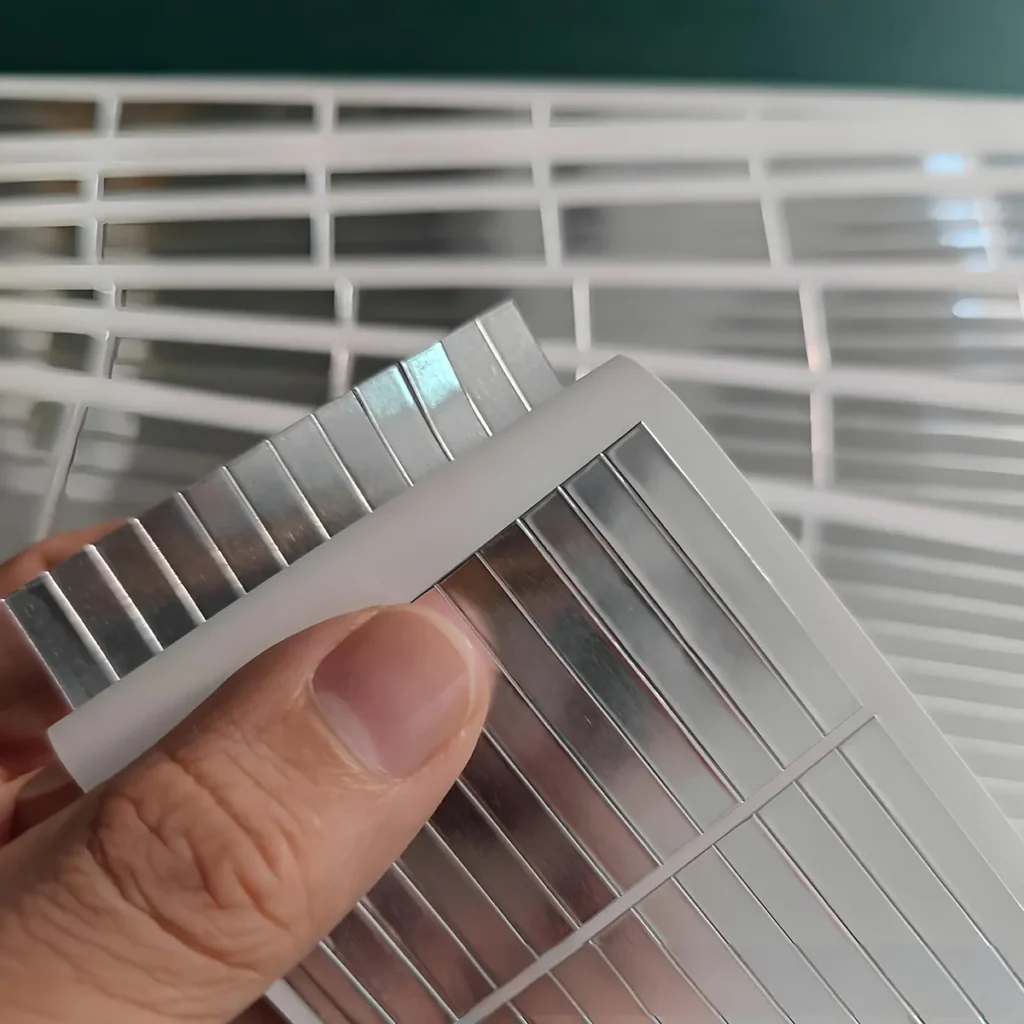

Aluminum Foil Tape Structure: Single-layer aluminum foil, anti-oxidation treated, with a pressure-sensitive adhesive backing. Thickness ranges between 0.05mm and 0.15mm, offering flexibility for various applications. Thinner options are ideal for precise electronic shielding, while thicker variants provide enhanced durability and insulation in demanding industrial settings. Features: This tape is lightweight and flexible, commonly used as duct sealing tape in HVAC systems, air conditioning, or ventilation systems. It offers excellent adhesion on smooth surfaces, preventing air leaks and protecting against heat loss. For enhanced performance, some variants include a release liner for easy application. Additionally, this tape is coated with a protective layer to improve durability and resistance to environmental factors.

Aluminum Foil Fiberglass Tape

Fiberglass-Reinforced Aluminum Foil Tape Structure: A composite of metal foil and fiberglass cloth, coated with a flame resistant adhesive. Features: Stronger and more durable, this tape is widely used as pipe insulation tape for industrial pipelines, offering superior performance in high temperatures or corrosive environments. Its superior construction also makes it an effective vapor barrier for protecting against moisture and temperature fluctuations.

Aluminum foil tape offers exceptional performance with its high-temperature resistance, moisture-proofing, corrosion resistance, thermal conductivity, and reflective properties. The typical temperature resistance for pure aluminum foil tape ranges from -20°C to 120°C (-4°F to 248°F), while fiberglass-reinforced aluminum foil tape can withstand higher temperatures, reaching up to 260°C (500°F). The temperature resistance of fiberglass tape depends primarily on the high-temperature adhesive used. Rubber adhesive provides excellent bonding strength in various conditions, while silicone adhesives allow the tape to remain stable at temperatures up to 250°C (482°F). Acrylic adhesive performs well up to 120°C (248°F) and offers the added advantage of clean removal with no residue.

The thickness of aluminum foil tape generally falls between 0.05mm and 0.15mm (0.002″ to 0.006″), with specific choices depending on the application requirements. Additionally, its outstanding solar and thermal reflectivity, often exceeding 90%, makes it an ideal material for both building insulation and industrial thermal protection. Common aluminum foil tape uses include sealing and protecting HVAC ducts, such as those in large commercial buildings to improve energy efficiency, providing electromagnetic shielding for electronic devices such as radio frequency equipment used in telecommunications, enhancing thermal insulation in construction projects like high-rise buildings to reduce energy loss, and protecting industrial equipment from heat exposure in manufacturing facilities. For example, it has been effectively utilized in automotive assembly lines to safeguard sensitive components from high temperatures. Some specialized variants, such as copper foil tape and lead foil tapes, cater to niche requirements, ensuring precise performance. Furthermore, die cut versions of the tape are available for customized applications where specific shapes or sizes are needed.

This versatile tape is durable, with independent tests demonstrating a lifespan exceeding 10 years in high-stress environments. Its proven reliability and resistance to extreme temperatures make it a preferred choice across industries, as noted by testimonials from leading HVAC and construction professionals.

What Is Foil Tape Used For?

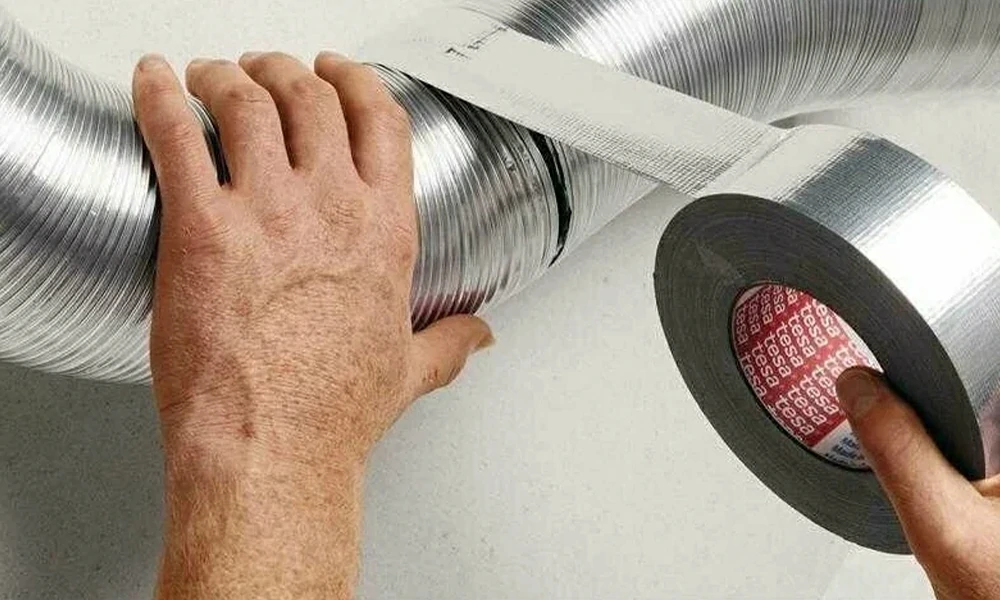

HVAC Systems (Duct Sealing Tape)

In HVAC systems, duct sealing tape ensures air-tight sealing of HVAC ducts, preventing leaks and securing insulation. Its pressure-sensitive adhesive and resistance to weather conditions and high temperatures make it essential for long-term performance. For example, during duct installations, fiberglass-reinforced tape (also known as high-temperature duct tape) ensures durability in high-heat scenarios like furnace systems.

Electronics Industry (Electromagnetic Shielding Tape):

Known in electronics as electromagnetic shielding tape, this metal foil adhesive tape, including copper foil tape and lead foil tapes, is vital for reducing EMI and RFI interference. It protects sensitive components like circuit boards and electrical cables, ensuring signal stability. For instance, in 5G devices, electromagnetic shielding tape isolates antenna modules, providing effective grounding and shielding.

Building Insulation (Thermal Insulation Tape)

In construction, thermal insulation tape seals insulation boards, minimizes energy loss, and improves energy efficiency. For example, during roof installations, pure aluminum tape creates airtight seals, preventing heat leakage and providing UV resistance. Its application in building insulation projects demonstrates its wide range of applications.

Industrial Pipelines (Pipe Insulation Tape)

In industrial sectors, pipe insulation tape, often reinforced with fiberglass, secures and protects high-temperature pipelines. This flame-resistant tape withstands up to 260°C (500°F) and is widely used to repair damaged insulation and prevent heat loss in chemical plants and energy facilities.

Aerospace (Thermal Protection Tape)

In aerospace, thermal protection tape, such as fiberglass-reinforced aluminum, is used for insulating engines, fuel systems, and other high-heat components. For example, during jet engine maintenance, this flame retardant tape provides lightweight, durable thermal barriers under extreme weather conditions.

Everyday Repairs (Multipurpose Repair Tape)

For household use, multipurpose repair tape is ideal for quick fixes like sealing window gaps, repairing exhaust pipes, or patching cracks. Lightweight aluminum foil tape (0.05mm to 0.08mm thick) ensures durability under heat and moisture exposure, offering reliable solutions for everyday problems.

Aluminum foil tape has proven itself as an indispensable material across industries, offering unparalleled versatility, durability, and efficiency. From duct sealing tape in HVAC systems to electromagnetic shielding tape in electronics, and from thermal insulation tape in construction to thermal protection tape in aerospace, its extensive applications demonstrate its ability to meet the demands of modern industries. Whether for high-temperature environments, harsh weather conditions, or precise electronic shielding, aluminum foil tape consistently delivers reliable results.

At WT, we are proud to be a leading manufacturer of aluminum foil tapes. Since 2002, we have been dedicated to the research and development of high-quality aluminum foil products. Our mission has always been to provide the market with cost-effective solutions, including aluminum foil tape, fiberglass-reinforced aluminum tape, and aluminum wire harness tape. With a deep understanding of the industry’s challenges and opportunities, we strive to deliver products that combine performance, affordability, and innovation.

For the latest industry solutions or to learn more about our products, we invite you to visit our aluminum foil tape store or connect with WT’s team of experts. Let us help you find the perfect aluminum foil tape to meet your specific needs and take your projects to the next level.