Introduction

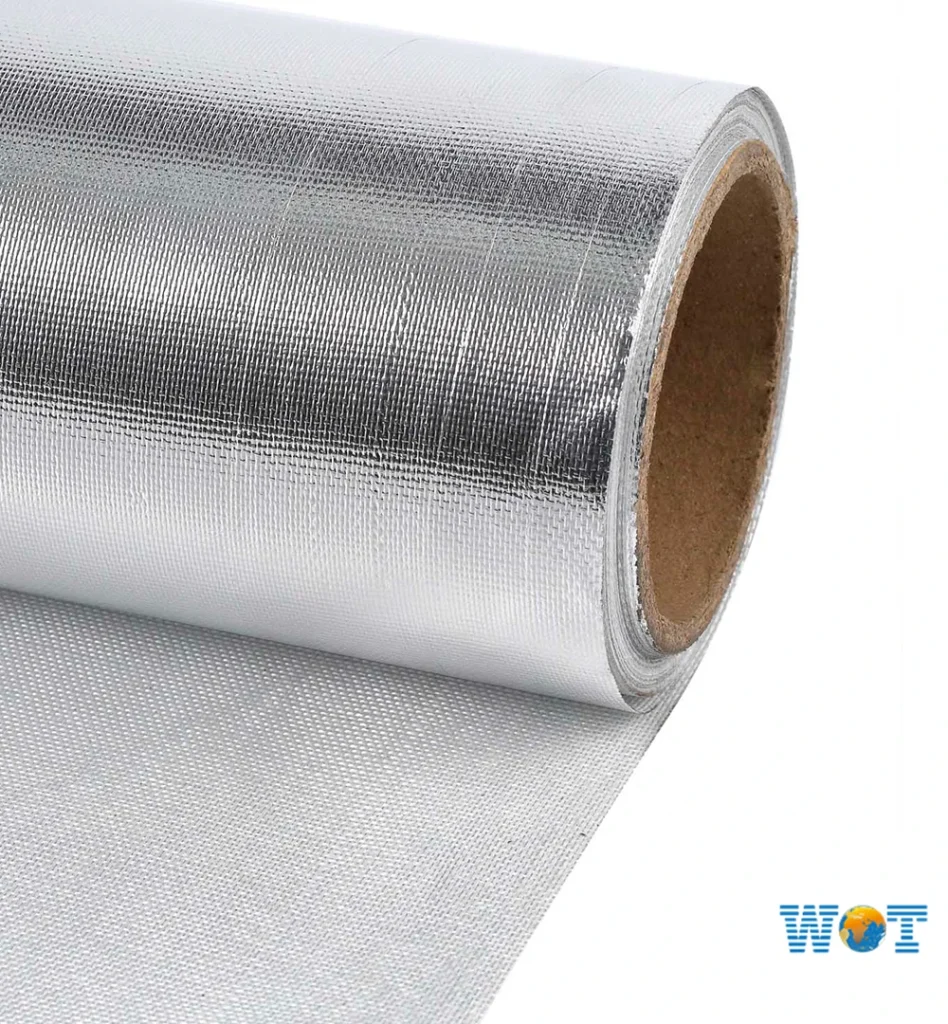

Aluminized fabric represents a significant advancement in the realm of composite materials, offering a blend of durability and thermal protection that is unmatched by traditional textiles. At its core, aluminized fabric is created by integrating aluminum into the fabric’s structure, which endows it with remarkable heat reflective properties. This innovative material is not only resistant to high temperatures but also provides a barrier against radiant heat, making it indispensable in industries where thermal management is critical.

The significance of aluminised fabric within the composite materials industry lies in its multifaceted functionality. It acts as a fireproof material, capable of withstanding intense heat and inhibiting the spread of flames. Additionally, its waterproof characteristics make it suitable for a variety of environmental conditions, further expanding its utility in the construction and manufacturing sectors.

Technical specifications underscore the performance of aluminized fabric, with data indicating its effectiveness in reflecting heat and maintaining structural integrity at temperatures exceeding 500 degrees Fahrenheit. This robustness, combined with its lightweight nature, positions aluminised fabric as a superior choice for applications requiring both fire resistance and thermal insulation.

In essence, aluminized fabric is a testament to the evolution of composite materials, providing a practical solution to the challenges of heat management and fire safety. Its unique attributes ensure that it remains a frontrunner in the industry, meeting the stringent requirements of modern engineering and design.

Regarding aluminized cloth, WT’s proficiency in thermal insulation composite materials positions the company to manufacture top-tier aluminized cloth that satisfies the rigorous standards of diverse industries. Equipped with state-of-the-art production machinery and a dedication to excellence, WT is poised to deliver an aluminized fabric that offers exceptional thermal defense and resilience, solidifying its status as a trailblazer in the realm of thermal insulation materials.

View our products: Aluminized Fabric

Definition and Composition

Aluminized fabric is a specialized material designed to provide exceptional thermal insulation and heat resistance. It is created by combining a base fabric, often made from materials like fiberglass, with a thin layer of aluminum. This process, known as aluminizing, involves the application of aluminum to the fabric, which can be achieved through various methods such as coating, lamination, or metallization.

The base fabric used in the production of aluminized material is typically a woven fiberglass cloth, chosen for its strength, durability, and inherent insulating properties. Fiberglass is an ideal substrate because it maintains its structural integrity across a wide range of temperatures and is resistant to many chemicals and environmental factors.

Learn More About:A Detailed Look at Different Types of Aluminized Fabric

The aluminizing process itself is a precise operation that requires specialized equipment and expertise. The aluminum layer is applied to the fiberglass cloth, creating a reflective surface that effectively bounces radiant heat away from the material. This not only enhances the fabric’s thermal insulation capabilities but also provides a degree of protection against direct flame and heat conduction.

Technical specifications for aluminized cloth often include data on thermal conductivity, emissivity, and temperature resistance. For example, high-quality aluminized fiberglass may have a temperature resistance of up to 1000°F (550°C), making it one of the best heat insulators available. The material’s low emissivity values, typically below 0.1, indicate its superior ability to reflect heat rather than absorb it.

In summary, aluminized fabric is a composite material that leverages the strength and insulation properties of fiberglass with the heat reflective qualities of aluminum. Its production involves a meticulous aluminizing process, resulting in a material that is among the most insulative and effective at thermal management in various industrial and commercial applications.

Learn More About: Exploring Aluminized Fabric: Definition and Composition

Properties and Benefits

Aluminized fabric exhibits a range of properties that make it an excellent choice for a variety of applications requiring thermal insulation and energy efficiency. Its primary characteristics include:

- Thermal Resistance: aluminized cloth is renowned for its exceptional thermal resistance, providing a barrier against heat transfer. This property is particularly valuable in high-temperature environments, where the material can effectively protect against heat damage and reduce energy consumption by minimizing the need for additional cooling measures.

Learn More About:Aluminized Fabric: A Game-Changer in Fire Resistance

- Electrical Insulation:Aluminized fabric can also serve as an electrical insulator, providing protection against electrical hazards. This makes it a safe choice for applications where electrical components are present, such as in wiring and cable insulation, further expanding its utility across various industries.

- Mechanical Strength:The base fabric used in aluminized materials, often fiberglass, contributes to the overall mechanical strength of the product. This strength allows aluminized fabric to withstand physical stress and maintain its shape, ensuring durability and longevity in demanding applications.

- Weight and Flexibility:Despite its robust properties, aluminized cloth remains lightweight and flexible, which are advantageous characteristics for ease of installation and use in space-constrained environments. These attributes also make it an excellent choice for applications where weight is a critical factor, such as in aerospace and automotive applications.

- Other Benefits:Beyond its primary properties, aluminized cloth offers additional advantages that enhance its value. It is inherently fire-retardant, providing a safer alternative in the presence of flames. Its reflective surface can also contribute to energy efficiency by reflecting light and reducing the need for artificial lighting in certain settings. Furthermore, the cost-effectiveness of aluminized cloth, combined with its long-term energy savings, makes it an economically viable option for thermal insulation

Applications of Aluminized Fabric

- Industrial Insulation: aluminized fabric widely used in industrial settings for insulating pipes and ducts, as well as boilers and vessels. Its high temperature resistance and reflective properties make it an effective solution for maintaining process temperatures and preventing heat loss. When applied to pipes and ducts, aluminized fabric helps to reduce energy consumption by minimizing the need for additional heating or cooling. For boilers and vessels, the fabric provides a protective layer that enhances safety and efficiency by reflecting radiant heat away from the outer surfaces.

- Building and Construction: In the building and construction industry, aluminized fabric is utilized for roofing and siding to improve energy efficiencyand for fireproofing applications to enhance structural fire safety. Its reflective surface can significantly reduce the heat absorbed by a building, leading to cooler indoor temperatures and reduced air conditioning needs. Additionally, when used as a fireproofing material, aluminized fabric can help to contain fires and prevent the spread of flames, providing valuable time for evacuation and limiting property damage.

- Electrical and Electronics: The electrical and electronics sectors benefit from aluminized fabric’s properties, using it for EMI shielding and wiring insulation. The fabric’s conductive aluminum layer can effectively block electromagnetic interference, ensuring the proper functioning of sensitive electronic equipment. As wiring insulation, it provides protection against electrical hazards and heat, contributing to the safety and reliability of electrical systems.

- Aerospace and Automotive: Aerospace and automotive applications leverage aluminized fabric for thermal protection systems and acoustic damping. In aerospace, the fabric’s lightweight and high-temperature resistanceare ideal for protecting spacecraft and aircraft components from extreme thermal conditions. In the automotive industry, aluminised fabric can be used to insulate exhaust systems and engine compartments, reducing heat transfer and noise, and improving vehicle performance and comfort.

- Other Niche Applications: Beyond these primary uses, aluminised fabric finds niche applications where its unique properties are advantageous. This includes uses in safety apparel, where it provides protection against radiant heat and flames, and in specialized packaging, where it helps to maintain temperature control and product integrity.

In each of these applications, aluminised fabric demonstrates its versatility and effectiveness as an insulating material. Its ability to withstand high temperatures, resist fire and chemicals, and provide energy savings makes it a valuable component in a wide range of industrial, commercial, and consumer products.

Installation and Usage

- Preparation and Surface Application: Before installing aluminized fabric, it is crucial to prepare the surface where the fabric will be applied. This involves cleaning the area to remove any dirt, grease, or debris that could compromise the adhesion of the fabric. Once the surface is clean and dry, the aluminized fabric can be carefully positioned, ensuring it covers the area effectively and aligns with any joints or seams.

- Cutting and Shaping Techniques: aluminised fabric can be cut to fit specific dimensions using sharp utility knives or scissors designed for cutting heavy-duty materials. When cutting, it is important to use a straightedge or template to guide the blade for precise cuts. The fabric can also be shaped to fit irregular surfaces by scoring and folding it along desired lines, taking advantage of its flexibility and durability.

- Adhesives and Mechanical Fasteners: To secure the aluminised fabric in place, adhesives specifically formulated for high-temperatureapplications can be used. These adhesives create a strong bond between the fabric and the surface, ensuring that the insulation remains intact over time. Additionally, mechanical fasteners such as stainless steel clips or pins may be employed in areas where adhesives are not suitable or where added security is required.

- Safety Precautions: When working with aluminized fabric, it is important to take appropriate safety precautions. This includes wearing protective gloves to prevent cuts from the sharp edges of the fabric and to protect hands from heat. Eye protection should also be worn to guard against small particles that may become airborne during cutting or shaping. Furthermore, when using adhesives or mechanical fasteners, it is essential to follow the manufacturer’s instructions to ensure safe and effective installation.

WT's aluminized cloth Product Line

WT Thermal Insulation Material Co., Ltd. offers a comprehensive range of aluminized cloth products designed to meet the diverse needs of various industries. Our product line is distinguished by unique features and advantages that set it apart from competitors.

- Description of Offerings:Our aluminized cloth is crafted from high-quality fiberglass cloth, which is then coated with a reflective aluminum layer. This combination creates a material that is not only lightweight and flexible but also highly resistant to heat and fire. Our fabrics are available in different thicknesses and widths, ensuring that we can cater to specific requirements for thermal insulation and fire protection.

- Unique Features and Advantages:WT’s aluminized cloth boasts superior reflective properties, making it an excellent insulator against radiant heat. It also exhibits excellent resistance to temperatures as high as 1000°F (550°C), making it suitable for extreme environments. Additionally, the fabric’s fire-retardant nature helps to prevent the spread of flames, contributing to fire safety in numerous applications.

- Customization Options Available: We understand that each application may have unique demands, which is why we offer customization options for our aluminized fabric. Clients can specify dimensions, coatings, and other features to ensure the fabric meets their exact needs. Our team works closely with customers to provide tailored solutionsthat optimize performance and efficiency.

- Quality Assurance and Certifications: WT is committed to maintaining the highest standards of quality. Our aluminized cloth undergoes rigorous testing to ensure it meets or exceeds industry standards. We are proud to hold relevant certifications that attest to the quality and reliability of our products. These certifications assure our clients that they are investing in a product that has been thoroughly vetted for performance and safety.

Learn More About:The Role of Technology in Aluminized Fabric Manufacturing

Maintenance and Longevity

- Inspection and Monitoring: Regular inspection of aluminized cloth essential to ensure its continued performance and longevity. This involves checking for signs of wear, tear, or damage that may compromise its insulating properties or fire resistance. Inspections should be conducted at intervals appropriate to the application and environment, with high-temperature or high-risk areas requiring more frequent checks.

- Repair and Replacement: Minor damages to aluminized cloth, such as small tears or punctures, can often be repaired using high-temperature adhesive patches or tapes. However, extensive damage may necessitate the replacement of the affected sections to maintain the integrity of the insulation. It is important to address any repair or replacement needs promptly to prevent further deterioration and to uphold safety standards.

- Cleaning and Preservation: aluminized cloth can be cleaned with mild detergents and water to remove dirt and debris. Care should be taken to avoid abrasive cleaners that could damage the fabric’s surface. After cleaning, the fabric should be allowed to dry completely before returning to service. Preservation of the fabric can be enhanced by applying a protective coating if recommended by the manufacturer, which can extend its lifespan by providing an additional barrier against environmental factors.

- Lifespan and Durability: The lifespan of aluminized cloth depends on various factors, including the quality of the material, the conditions of its use, and the maintenance it receives. High-quality aluminized fabric, when properly maintained, can offer a durable solution with a lifespan that exceeds traditional insulation materials. Manufacturers may provide specific longevity data based on testing and real-world applications, which can guide users in understanding the expected performance over time.

Environmental Considerations

- Sustainability of aluminized cloth:The sustainability of aluminized cloth is a key factor in its environmental impact. Manufactured from materials like fiberglass and aluminum, which are known for their durability and longevity, aluminized fabric offers a sustainable solution for thermal insulation and fire protection. Its ability to reduce energy consumption by minimizing heat loss contributes to a reduction in greenhouse gas emissions associated with heating and cooling buildings.

- Recyclability and Waste Reduction: aluminized cloth is designed to be long-lasting, which inherently reduces the frequency of replacement and the generation of waste. Additionally, the materials used in its production, such as aluminum, are highly recyclable. At the end of its useful life, aluminized fabric can be recycled, further reducing its environmental footprint. This recyclability supports circular economy principles by conserving resources and minimizing waste.

- Impact on Energy Conservation: The use of aluminized cloth in insulation applications can significantly enhance energy efficiency. Its reflective properties help to maintain desired temperatures within spaces, reducing the need for artificial heating and cooling. This results in lower energy bills for consumers and businesses, and a collective reduction in energy demand on a larger scale. The conservation of energy through the use of aluminized fabric supports efforts to reduce the strain on power grids and decrease reliance on non-renewable energy sources.

In summary, aluminised fabric’s sustainability, recyclability, and positive impact on energy conservation make it an environmentally responsible choice for insulation and fire protection. Its role in reducing energy consumption and waste aligns with global efforts to combat climate change and promote a more sustainable future.