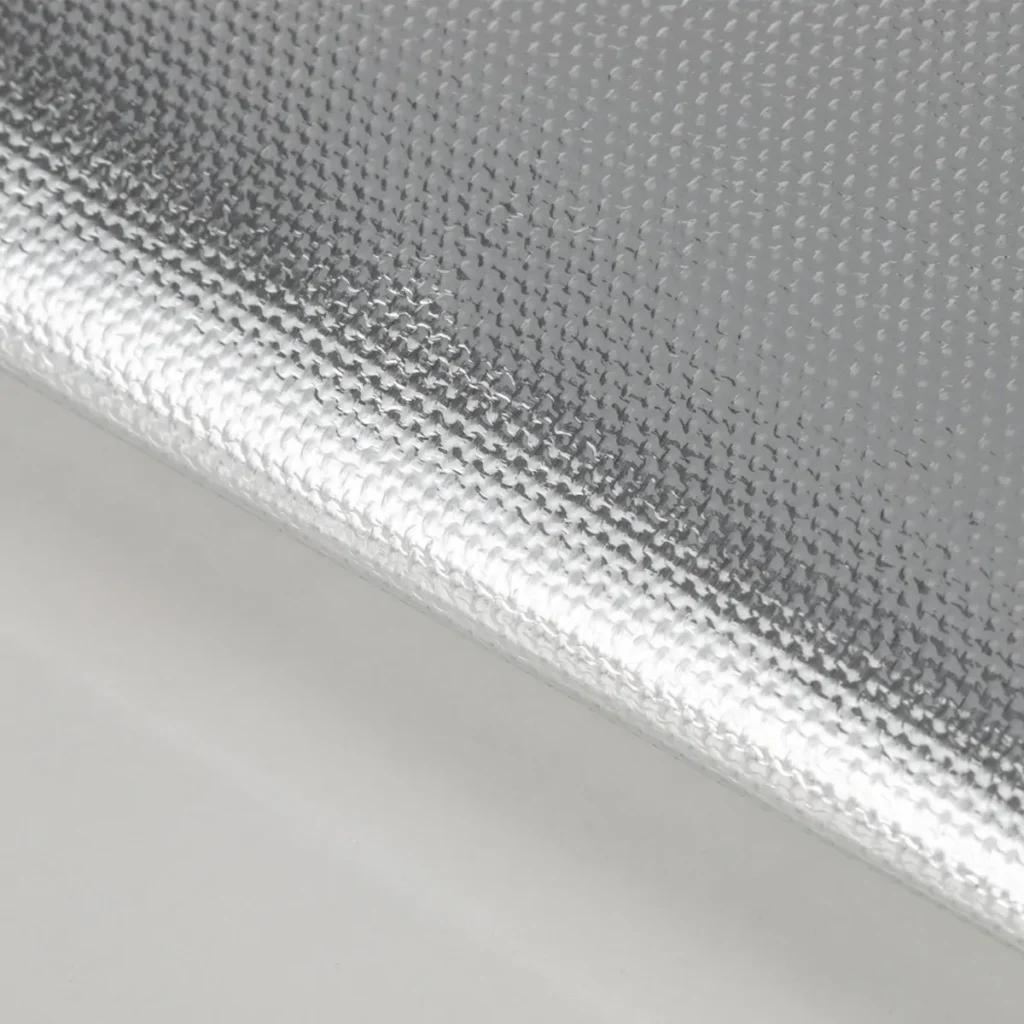

Aluminum Foil Fiberglass Fabric

WT offers aluminum foil fiberglass fabrics with thicknesses ranging from 0.005″ to 0.08″ (with a weight range of 2.2 oz/yd² to 33 oz/yd²). Aluminum fabrics serve as thermal insulation materials and provide excellent protection for personnel and equipment in high heat and radiant heat environments.

WT’s aluminum foil fabric uses a specialized lamination process that bonds an aluminum-coated film to one or both sides of a fiberglass cloth or other base material. This process enhances the material’s heat reflective capability and heat resistance. The aluminum foil layer can endure temperatures up to 487°F (253°C), while the high-temperature adhesive withstands up to 350°F (175°C). As such, WT recommends using aluminum foil fiberglass cloth in static or insulating applications where its properties excel.

WT also provides custom services and industry-specific solutions for aluminum foil fabrics, which are widely used in casting curtains, molten metal splash protection, expansion joints, mechanical insulation covers, and other applications.

Aluminum Film Backed Fabric

Provides seamless protection against radiation heat sources and chemical/oily environments.

CERTIFIED

WT’s aluminum foil fiberglass fabric is UL94 VTM0 certified.

HEAT RESISTANCE

Indirect temperature resistance up to 3000°F (1650°C).

THERMAL REFLECTION

Thermal radiation reflectivity of 97% (ASTM C1371-15).

DURABILITY

Excellent chemical resistance and abrasion resistance.

Standard series

| NO. | IMG | Basic Fabric | Weight | Thickness | Width(in) | Direct | Indirect |

|---|---|---|---|---|---|---|---|

| AL-2728 |  | 2728 Fiberglass Fabric (Plain) | 5.8 oz/yd² (200 g/m²) | 0.08″(0.2 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-3732 |  | 3732 Fiberglass Fabric (3×1 TWIL L) | 12.7 oz/yd² (430 g/m²) | 0.0017 ″(0.43 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-75 |  | Fiberglass Fabric (Plain) | 2.2 oz/yd² (75 g/m²) | 0.005″(0.12 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-85 |  | Fiberglass Fabric (Plain) | 2.5 oz/yd² (85 g/m²) | 0.005″(0.12 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-110 |  | Fiberglass Fabric | 3.2 oz/yd²(110 g/m²) | 0.006″(0.15 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-3784 |  | Fiberglass Fabric | 26.4 oz/yd² (880 g/m²) | 0.03″(0.9 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-FW600 |  | Fiberglass Fabric (Grid) | 17.6 oz/yd² (600 g/m²) | 0.02″(0.55 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-HT2025 |  | Fiberglass Fabric (Plain) | 17.9 oz/yd² (610 g/m²) | 0.03 ” (0.75 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

| AL-M33 |  | Fiberglass Fabric (Plain) | 33 oz/yd² (1120 g/m²) | 0.059″(1.5 mm) | 38,40,48,60 | 350°F(175°C) | 3000°F(1650°C) |

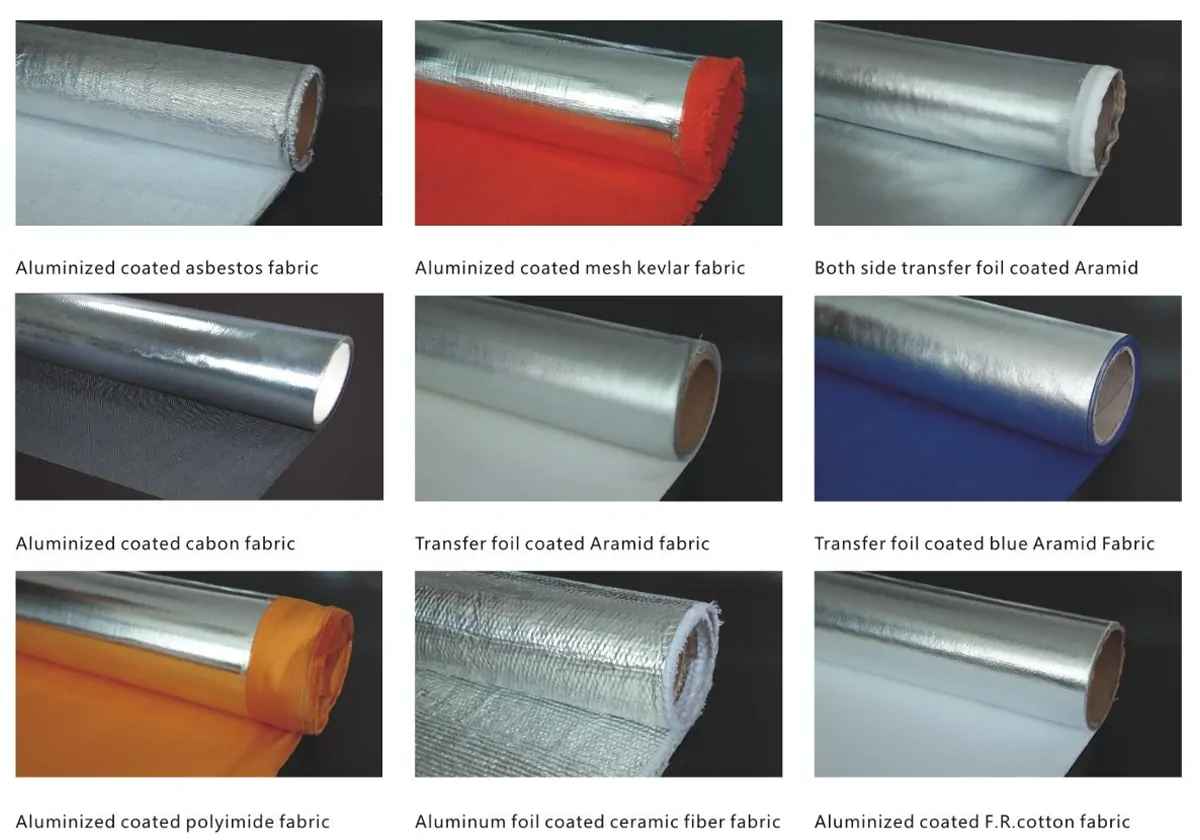

High Temperature Series

| Project | Technical Parameters | Imperial Units |

| Aluminum Foil Thickness | 12 µm / 18 µm / 25 µm | 0.472 mil / 0.709 mil / 0.984 mil |

| Coating Type | Aluminum foil / Aluminum film / Flame-retardant aluminum film | Aluminum foil / Aluminum film / Flame-retardant aluminum film |

| Fabric Types | Kevlar fabric, Aramid fabric, Carbon fiber fabric, High silica fabric, Blended fabric, Ceramic fiber fabric | Kevlar fabric, Aramid fabric, Carbon fiber fabric, High silica fabric, Blended fabric, Ceramic fiber fabric |

| Width | 1m, 1.2m, 1.3m, 1.5m | 3.281 ft, 3.937 ft, 4.265 ft, 4.921 ft |

| Length | 30m, 50m, 100m | 98.43 ft, 164.04 ft, 328.08 ft |

| Main Features | – Smooth, high-reflectivity aluminum foil surface | – Smooth, high-reflectivity aluminum foil surface |

| – High tensile strength in both directions | – High tensile strength in both directions | |

| – Airtight, waterproof, good sealing performance | – Airtight, waterproof, good sealing performance | |

| Applications | Firefighting, Environmental protection, High-temperature protection | Firefighting, Environmental protection, High-temperature protection |

Flame Spread Testing:ASTM E84

Convective Heat Testing:ASTM F2700

Radiant Heat Testing:ASTM F1939

Abrasion Resistance Testing:ASTM D3884

Tear Resistance Testing:ASTM D624

Molten Metal Testing:ISO 9185

Structure and Features

WT’s aluminum foil fiberglass fabric offers exceptional performance in extreme high heat environments. Engineered to handle continuous temperatures up to 2912°F (1600°C) on the fiberglass cloth side, it provides reliable thermal insulation and heat shielding for demanding applications such as heat-resistant metal casting, industrial safety apparel, and heat shields for molding and firefighting operations.

The aluminum foil surface is specifically designed to resist temperatures up to 300°F (150°C), making it ideal for proximity suits and molten metal splash protection in industries handling molten materials. Exceeding this threshold may impact the heat reflective and structural integrity of the foil. However, the fiberglass base fabric maintains its stability and thermal insulation properties up to 1022°F (550°C), ensuring consistent protection against radiant heat and extreme thermal conditions.

WT’s aluminum foil fiberglass cloth complies with international safety standards, including:

- ISO 9151: Assesses heat shielding and thermal insulation effectiveness.

- ISO 15025: Evaluates limited flame spread performance.

- ISO 6942: Ensures resistance to high temperature environments.

Talk to WT's Experts

We are fully prepared with all the resources and solutions for your industry needs.

The difference between Aluminum Foil Laminated Fabric and Aluminized Fabric

Aluminum Foil Laminated Fabric

Aluminum foil laminated fabric is made by bonding aluminum foil to a base fabric (e.g., fiberglass cloth) using a lamination process. This material provides superior heat reflective and thermal insulation properties, making it ideal for high-temperature and harsh environmental applications.

Key Features:

- Reflects up to 95% of radiant heat.

- Temperature Resistance: Aluminum foil layer up to 487°F (253°C); base fabric (e.g., fiberglass) up to 1022°F (550°C).

- Highly resistant to moisture, corrosion, and UV radiation.

- Thickness: 0.005″ to 0.08″; Weight: 2.2 oz/yd² to 33 oz/yd².

Applications:

- Thermal insulation materials for buildings, industrial piping, and HVAC systems.

- Protective gear for molten metal handling and high-heat environments.

- Equipment shielding from thermal damage and radiant heat.

Aluminized Fabric

Aluminized fabrics are created by spraying or depositing aluminum powder onto a base fabric, offering lightweight heat shielding and flexibility. These fabrics are suited for dynamic applications requiring UV protection and thermal reflectivity.

Key Features:

- Reflects up to 90% of radiant heat.

- Temperature Resistance: Aluminum layer up to 392°F (200°C); base fabric up to 572°F (300°C).

- Lightweight with excellent UV resistance.

Applications:

- Protective clothing (e.g., firefighter suits, proximity suits).

- Thermal insulation materials for vehicles, aerospace, and energy-saving construction.

- Heat shields for high-light and high-heat environments.

Application

| Product | Industry | Function |

|---|---|---|

| Thermal insulation wraps | Construction & Building | Thermal regulation, equipment protection |

| Fire curtains or blankets | Fire Safety & Industrial Settings | Fire protection |

| Heat-resistant suits & gloves | Personal Protective Equipment | Protection against high temperatures |

| Insulated foil bags and wraps | Food Service & Pharmaceuticals | Temperature maintenance for food and medication transport |

| Heat shields and engine covers | Automotive | Protection from heat, noise reduction |

| Thermal insulation for spacecraft | Aerospace | Protection against extreme space temperatures |

| Reflective panels for solar applications | Renewable Energy | Enhancing efficiency of solar thermal systems |

| Insulation materials for ships | Maritime | Safety and comfort improvement onboard |

| Sound dampening panels | Construction & Automotive | Noise reduction and acoustics enhancement |

| Insulating covers for wiring | Electronics & Electrical | Preventing heat damage, fire risk protection |

| Emergency thermal blankets | Outdoor & Emergency Preparedness | Thermal insulation in survival situations |

sales@wtinsulation.com

Phone

0086-13771601681

Address

No.5,North Waihuan Road,Huangtang Industrial Zone, Xuxiake Town, JiangYin City, Jiangsu Province, China