Phenolic Insulation Board

The Best Materials For Air Ducts And Exterior Walls

Phenolic insulation board is renowned for its exceptional thermal performance, helping to meet stringent building regulations. Its versatility allows it to be applied in roofs, walls, and floors, making it an excellent choice for diverse construction projects, particularly in commercial buildings. With certification from UL181 testing, WT’s panels deliver superior quality and reliability while being environmentally friendly, as they are free of CFCs and HCFCs.

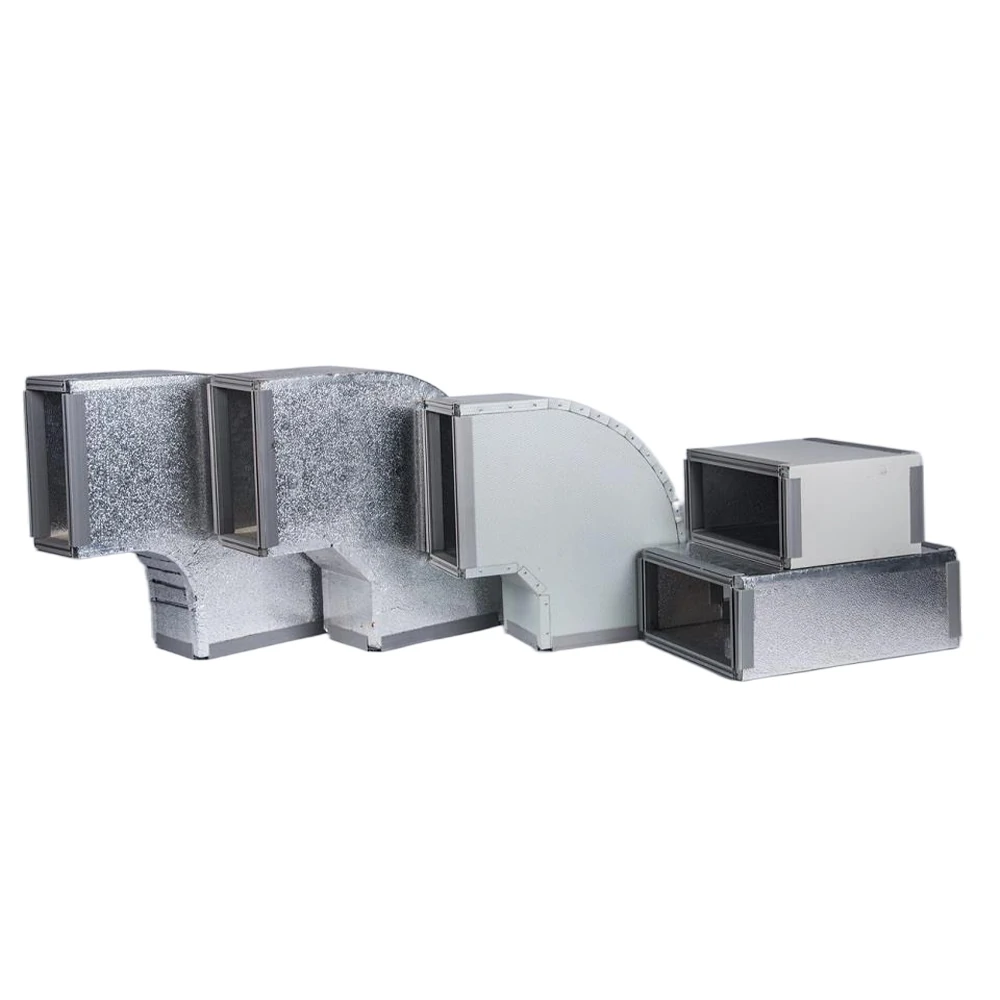

WT’s phenolic insulation boards include central duct phenolic composite panels and phenolic exterior wall panels. Designed for high-performance use, these phenolic foam insulation solutions are ideal for HVAC duct systems, interior walls, and exterior insulation applications.

UL181 CERTIFIED

Features of Phenolic Insulation Board

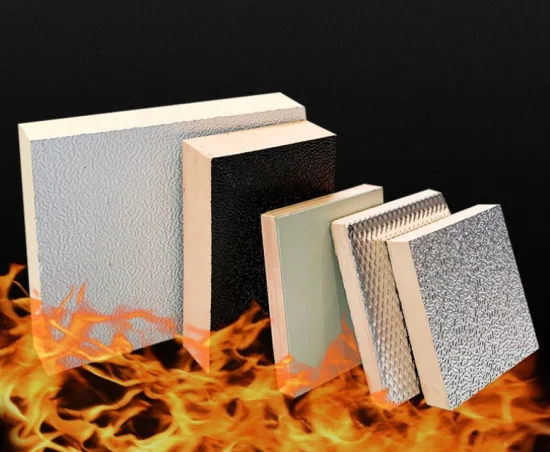

Flame Retardant

As a naturally flame-retardant material, phenolic foam insulation does not drip during combustion and generates minimal smoke, with significantly reduced toxic gas emissions. It boasts an oxygen index of ≥40 (test standard: ASTM D2863), a smoke density level of ≤10 (test standard: ASTM E662), and meets the UL94 V-0 flame retardant level (test standard: UL94).

High Temperature Resistance

The phenolic board is engineered for excellent heat resistance, maintaining its mechanical and electrical properties in high-temperature environments. Its operating temperature range is -50°C to 150°C (-58°F to 302°F), while special formulations can withstand even higher temperatures (test standard: ASTM D573). With a thermal decomposition temperature of ≥350°C (≥662°F) (test standard: ISO 11357), it is a thermally efficient and reliable insulation

High Strength

The phenolic insulation board provides excellent structural integrity, offering high compressive, flexural, and impact strength. These rigid insulation materials perform consistently across a wide range of temperatures. It meets industry standards with a compressive strength of ≥100 MPa (14,500 psi) (test standard: ASTM D695), flexural strength of 80-150 MPa (11,600-21,750 psi) (test standard: ASTM D790), and impact strength (notched) of 8-15 kJ/m² (3.8-7.1 ft·lbf/in²) (test standard: ASTM D256).

Electrical Insulation

Phenolic boards excel in electrical insulation, remaining stable under humid, high-temperature, or high-pressure conditions. They feature dielectric strength ≥15 kV/mm (381 V/mil) (test standard: ASTM D149), volume resistivity ≥10¹² Ω·cm (≥10¹⁵ Ω·in) (test standard: ASTM D257), and a dielectric constant of 3.8-4.5 (50 Hz) (test standard: ASTM D150).

High Resistance to Moisture and Weather Conditions

With its high closed cell content, the phenolic insulation board resists moisture penetration, maintaining its integrity in humid environments. This feature enhances its durability and makes it ideal for use in weather-exposed settings.

Easy to Process

The phenolic board features a low density, allowing it to be easily cut, drilled, and machined into complex structures as required. With a density range of 1.3-1.8 g/cm³ (81.2-112.4 lb/ft³) (test standard: ASTM D792), it is also simple to coat and bond, making it versatile for various industrial and construction applications.

Weather Resistance and Dimensional Stability

Even in varying temperature and humidity environments, phenolic boards exhibit minimal dimensional changes. They resist aging and deformation, maintaining long-term performance. Water absorption rate ≤1% (24 hours) (test standard: ASTM D570), and linear expansion coefficient 1.2-3 × 10⁻⁵ /K (test standard: ASTM E831) ensure stability and durability.

Chemical Resistance

The rigid phenolic foam resists corrosion from acids, alkalis, and organic solvents, making it an excellent choice for corrosive environments. For instance, when immersed in 10% H₂SO₄ or 10% NaOH, the mass change rate is less than 0.5% (test standard: ASTM D543), ensuring long-term durability in harsh conditions.

Environmental Protection and Energy Efficiency

WT’s phenolic foam insulation materials are eco-friendly, producing minimal harmful emissions during processing and use. Formaldehyde emissions are ≤0.1 mg/L (E0 environmental standards) (test standard: EN 717-1), and the smoke toxicity index is exceptionally low (ASTM E800). By contributing to better energy efficiency, these thermally efficient materials are a sustainable choice for modern construction projects.

| Inspection Items | Technology Index |

|---|---|

| Fire Ratings Becnh Mark 25/50 BS 476 | BS 476: Part 6 &7 |

| Thermal Conductivity | 0.021W/(mk) |

| Water Absorption | <3.7% |

| Heat Resistance | -150~+150℃(-300℉~300℉) |

| Wind Resistance | ≤1500Pa |

| Compression Strength | ≥0.18MPa |

| Bending Strength | ≥1.1MPa |

| Leakage Air Volume | ≤1.2% Class 2 |

| Thermal Resistance | 0.86 m³k/w |

| Smoke Density | ≥9 (Non Toxic Gas Release) |

| Dimension Stability | ≤2%(70±2℃/48h)(158±35.6℉/48h) |

| Oxygen Index | ≥45 |

| Duration of Fire Resistance | ≥1.5h |

| Formaldehyde Emission | ≤0.5Mg/L |

| Air Flow | 15M/S(49.2126 feet/s) |

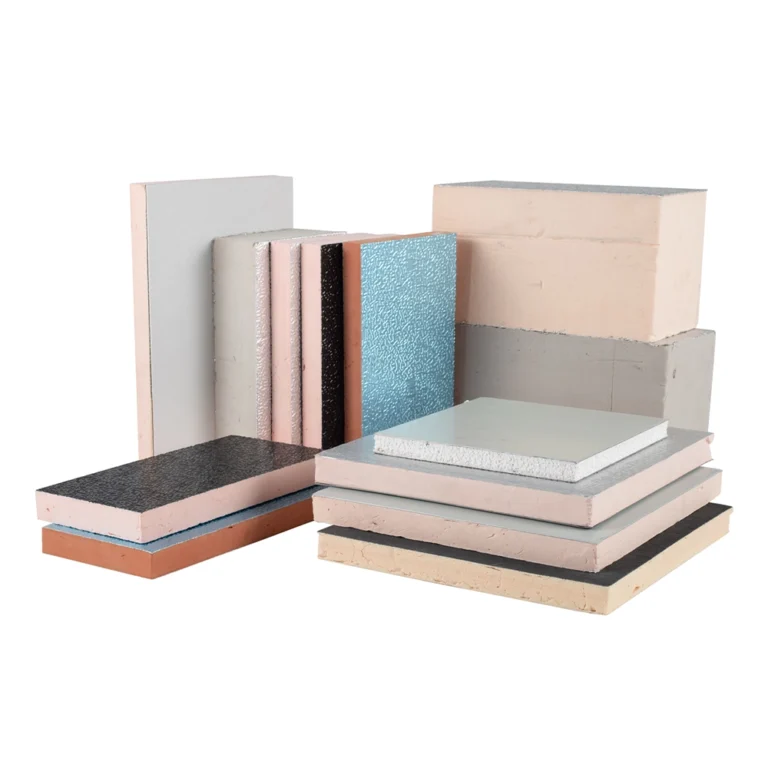

Types of Phenolic Insulation Board

WT offers two types of phenolic insulation board: phenolic duct board for HVAC systems (thinner) and phenolic exterior wall board for exterior wall insulation (thicker).

Phenolic Pre Insulated Duct Boards

- UL 181 Listed

- Standard Thickness:20mm(0.7874 Inches), 25mm(0.9843 Inches), 30mm(1.1811 Inches) (Customizable)

- Settlement Density: 50-65 Kg/M³

- Temperature Resistance:-150℃~150℃(-300℉~300℉)

- Thermal Conductivity: 0.019-0.02w/(M/K)

Phenolic External Wall Insulation Boards

- Thickness: 0.025/0.04/0.06/0.08mm

- Heat Resistance: -150℃~150℃(-300℉~300℉)

- Core Density: 40-60Kg/m³

- Leakage Air Volume: ≤1.2%

- Smoke Density: ≤9(Non Toxic Gas Release)

WT - Your Trusted Solution for Phenolic Duct and Wall Panels

Whether you need high-performance duct panels, wall panels, custom designs, or large-scale production, we provide professional support tailored to your needs!

- Free product quotes

- Free custom solution design

- Free technical consultation

- One-stop manufacturing solutions

Why choose us?

- Years of expertise in producing premium phenolic panels.

- Products meet international standards, widely used in construction and industrial applications.

- Professional team offering comprehensive technical support.

Contact us today!

- Get free quotes and sample support

- Consult our experts for tailored solutions

- Explore more partnership opportunities!

WT — Your trusted partner in phenolic panel manufacturing!