Aluminum Foil Tape

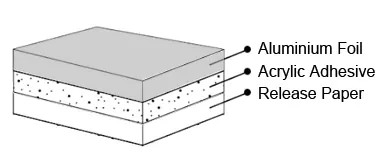

Aluminum foil tape provides unparalleled sealing and insulation capabilities. Our foil tape, including white tape and foil insulation tape options, is fiberglass-free and crafted from high-grade aluminum foil, adhesive, and release paper.

You can choose between acrylic pressure-sensitive adhesive or silicone adhesive for your foil-faced insulation tape, ensuring reliable solutions for a variety of applications. These include air ducts, HVAC systems, dryer vents, and rigid metal panels pipeline. Our UL181 compliance certification guarantees the highest quality and performance standards for all our foil insulation tape products.

Aluminum Foil Tapes

Non-fiberglass aluminum foil tape offers lightweight flexibility, safe handling, clean edge integrity, and superior thermal reflectivity for demanding applications.

LIGHTWEIGHT FLEXIBILITY

Fiberglass-free design reduces weight to 150-250 g/m² with superior flexibility, ideal for complex surfaces and dynamic uses like aerospace and automotive harnesses.

SAFE HANDLING

No fiberglass eliminates dust or particle release, compliant with ISO 14644-1, suitable for cleanrooms, precision electronics, and food-grade sealing.

EDGE INTEGRITY

High-strength composite ensures peel strength >20 N/25mm, with no fraying or delamination, ideal for semiconductor and precision industrial seals.

THERMAL REFLECTIVITY

Reflectivity up to 97% (ASTM C1371) with <0.8 μm surface roughness, perfect for thermal shielding in optical devices and solar collectors.

| Item No. | Description | Backing Micron | Thickness Micron | Adhesive | Applicable Temperature |

|---|---|---|---|---|---|

| AF1825 | Foil Solvent Acrylic Adhesive Silicone Release | 18u | 55u | Solvent Acrylic Flame-Retardant | -30~120℃ |

| AF2225 | 22u | 60u | -30~120℃ | ||

| AF2525 | 25u | 65u | -30~120℃ | ||

| AF1825 | 30u | 70u | -30~120℃ | ||

| AF3625 | 36u | 76u | -30~120℃ | ||

| AF4025 | 40u | 80u | -30~120℃ | ||

| AF4525 | 45u | 85u | -30~120℃ | ||

| AF5025 | 50u | 90u | -30~120℃ | ||

| AF7525 | 75u | 125u | -30~120℃ | ||

| AF10025 | 100u | 150u | -30~120℃ | ||

| AF12525 | 125u | 175u | -30~120℃ |

STRUCTURE & SPECIFICATIONS

- CUT ROLL: 48 /50mm (2″) / 60 / 63mm (2.5″) / 72 / 75mm (3″) / 96mm /100mm (4″) adhesive with strong adhesion and holding power offers permanent sealing and bonding on Foil-Scrim-Kraft Facing joints and seams in HVAC ductwork application.

- LOG ROLL: 1200mmx45/50m

- JUMBO ROLL: 1200mm x1000m/1200m/1350m

- STORAGE & SHELF LIFE: 12 months when stored at 21℃ (70F) /50% relative humidity out of direct sunlight.

Why Choose Foil Tape?

Extreme temperature resistance

Aluminum foil tape offers exceptional performance in extreme temperatures, withstanding a range from -30°C (-22°F) to 550°C (1022°F). The aluminum layer provides excellent heat dissipation and reflectivity, achieving up to 97% thermal radiation reflectance (ASTM C1371). This makes it indispensable for HVAC duct sealing, industrial insulation, and thermal shielding in high-temperature applications.

Moisture and Vapor Barrier

The dense aluminum structure provides impermeable protection against water, vapor, and air infiltration. Tested to ASTM E96 standards, aluminum foil tape achieves a water vapor transmission rate (WVTR) of <0.02 g/m²·24h. This makes it ideal for creating airtight seals in HVAC systems, reducing energy loss, and improving system efficiency.

High Adhesion and Bonding Strength

Featuring advanced acrylic or silicone adhesives, aluminum foil tape delivers peel strengths exceeding 20 N/25mm (ASTM D3330). It adheres securely to metal, plastic, and composite surfaces, even in freezing or humid environments. Its cohesive strength ensures long-term reliability in dynamic or static applications, such as piping insulation and equipment sealing.

Structural Durability

Engineered with a tensile strength of over 450 N/50mm (ASTM D882), aluminum foil tape resists tearing, punctures, and abrasion. Its robust structure ensures durability in heavy-duty applications, such as protective wrapping for mechanical components and industrial equipment.

Chemical and UV Resistance

With excellent resistance to oils, acids, and alkaline substances, aluminum foil tape is designed for chemically aggressive environments. It maintains stability under prolonged UV exposure, making it suitable for outdoor and industrial applications such as pipeline wrapping and chemical plant maintenance.

Eco-Friendly and Sustainable

Aluminum foil tape is 100% recyclable, with a recycling energy requirement of just 5% compared to initial production. Its eco-friendly composition aligns with modern sustainability goals, making it a preferred choice for green building and manufacturing projects.

Applications Of Foil Tape

1. HVAC Systems – Duct Sealing and Insulation Wrapping

Aluminum foil tape is essential in HVAC systems for creating airtight seals and wrapping duct joints. Its high thermal reflectivity (up to 97%) and moisture barrier properties ensure energy efficiency by preventing air and heat leakage. Certified to UL181 standards, it is a preferred choice for insulation wrapping and ductwork in both residential and commercial buildings.

2. Industrial Thermal Shielding

The exceptional heat resistance of aluminum foil tape (up to 550°C/1022°F) makes it ideal for shielding sensitive components in high-temperature industrial environments, such as furnaces, boilers, and exhaust systems. Its ability to reflect radiant heat reduces surface temperatures, protecting nearby equipment and personnel.

3. Aerospace and Automotive Heat Management

Aluminum foil tape’s lightweight structure and high-temperature stability are indispensable for heat shielding and insulation in aerospace and automotive applications. It is commonly used for wrapping wiring harnesses, insulating engine compartments, and protecting electronic components from thermal damage.

4. Chemical and Corrosive Environment Protection

Thanks to its resistance to acids, alkalis, and oils, aluminum foil tape is widely used in chemical plants and oil refineries to protect piping and components from corrosion. Its impermeable aluminum barrier ensures long-term durability in aggressive chemical environments.

5. Cleanroom and Hygienic Applications

The fiberglass-free and dust-resistant structure of aluminum foil tape makes it suitable for cleanroom environments, such as pharmaceutical and semiconductor manufacturing. It provides contamination-free sealing and insulation for sensitive equipment.

6. Electrical Shielding in Electronics

Aluminum foil tape is commonly used for EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) shielding in electronics and communication equipment. Its conductive aluminum layer minimizes signal loss and interference, ensuring stable performance in sensitive circuits.

7. Reflective Layer in Solar Panels

The high reflectivity and UV resistance of aluminum foil tape make it an excellent material for enhancing solar panel efficiency. It is used as a reflective layer to maximize sunlight absorption and heat management in solar power systems.

8. Fireproof and Smokeproof Sealing

Certified for flame retardance (UL723 and UL181), aluminum foil tape is widely applied in fireproof doors, smoke barriers, and fire-rated construction assemblies to contain and control fire spread in buildings.

9. Soundproofing and Acoustic Applications

Aluminum foil tape, when paired with sound-dampening materials, provides a vapor-tight seal and enhances acoustic insulation in automotive cabins, recording studios, and machinery housings, reducing noise transmission effectively.

10. Food Packaging and Cold Storage

Its moisture-proof and thermal stability make aluminum foil tape a go-to solution in the food and beverage industry for sealing cold storage insulation, ensuring consistent temperature and hygiene in storage and transportation.

sales@wtinsulation.com

Phone

0086-13771601681

Address

No.5,North Waihuan Road,Huangtang Industrial Zone, Xuxiake Town, JiangYin City, Jiangsu Province, China