What is the Best Insulation for Exterior Walls?

Insulating a home is like armoring it against the elements. With the push for energy-efficient living, homeowners must decide on the best exterior wall insulation. This choice affects comfort, energy savings, environmental impact, and home value. Fiberglass and foam board are popular options, but what is the best insulation for exterior walls?

What Kind Of Insulation For Exterior Walls?

When doing exterior wall insulation projects, the selection of insulating materials is crucial. Excellent system insulation projects do not only observe the only indicator: thermal conductivity, but also need to make reasonable building insulation project designs based on the performance characteristics of the insulating materials and the use environment.

Fiberglass Insulation

Batt Insulation: Typically has an R-value ranging from R-11 to R-15 for 3.5 inches of thickness, making it suitable for standard wall cavities.

Loose Fill: Offers an R-value of about R-2.2 to R-2.7 per inch. It requires a professional blow-in process, which ensures a complete fill.

Spray Foam Insulation

- Open Cell: Has a lower density with an R-value of approximately R-3.5 per inch. It’s air-permeable and can accommodate a degree of moisture.

- Closed Cell: Denser and more moisture-resistant, with a higher R-value of around R-6 to R-7 per inch, expanding to create an airtight seal.

Foam Board Insulation

- Materials such as polystyrene (R-5 per inch), polyisocyanurate (R-5.6 to R-8 per inch), and polyurethane (R-5.5 to R-6.5 per inch).

- Rigid Panels: Can be applied externally or internally to the wall cavities, often used in conjunction with other insulation to prevent thermal bridging.

Phenolic Insulation Board (PF Board)

- Type: Organic insulation material

- Key Performance:

- Thermal conductivity: Approximately 0.022–0.030 W/(m·K)

- Fire resistance: Class B1 (near Class A standards for fire resistance)

- High strength, low density, with a closed-cell structure

- Advantages:

- Low thermal conductivity, delivering exceptional thermal insulation performance

- Superior fire resistance, with high-temperature stability

- Lightweight and moisture-resistant

- Environmentally friendly with zero chlorofluorocarbon (CFC) emissions

- Disadvantages:

- Brittle and prone to cracking, limiting impact resistance

- Edges and corners require careful protection during installation

- Relatively higher cost compared to conventional materials

- Suitable Applications:

- Recommended for external wall insulation systems in buildings requiring high fire safety

- Widely applied in public buildings and residential projects focusing on energy efficiency

- Especially suited for temperature-sensitive environments, such as cold chain logistics buildings

Magnesium Oxide Board (MgO Board)

- Type: Inorganic insulation material

- Key Performance:

- Thermal conductivity: Approximately 0.065 W/(m·K)

- Fire resistance: Class A (non-combustible)

- Strength and durability: High compressive strength, impact resistance, and dimensional stability

- Advantages:

- Superior fire resistance, classified as Class A, making it non-combustible under extreme heat

- High moisture resistance, suitable for humid or wet conditions

- Excellent mechanical strength, providing durability and stability

- Eco-friendly, non-toxic, and easy to install in diverse construction settings

- Disadvantages:

- Relatively higher thermal conductivity limits its insulation performance

- Production processes may result in cracking issues, requiring stringent quality control

- Higher cost compared to mainstream insulation materials

- Suitable Applications:

- Ideal for environments with high fire resistance demands, such as industrial buildings and public facilities

- Perfect for humid and wet applications, including basements, bathrooms, and external wall systems

- Widely employed in lightweight steel structures and prefabricated modular construction

Cellulose Insulation

Loose Fill: Offers an R-value of about R-3.2 to R-3.8 per inch. It’s treated for fire resistance and contains up to 85% recycled content.

Wool Insulations

Natural sheep’s wool has an R-value of R-3.5 to R-3.8 per inch, while rock wool has an R-value of around R-3.0 to R-3.3 per inch. Wool is moisture-tolerant, absorbing up to 35% of its weight without losing insulative properties.

Energy Savings with Insulation

These materials can significantly reduce energy costs by maintaining indoor temperatures, reducing reliance on heating and cooling systems. A well-insulated home can cut heating and cooling expenses by up to 15%, according to the U.S. Environmental Protection Agency.

| Material Type | Thermal Conductivity (W/m·K) | Fire Rating | Key Advantages | Application Scenarios | Key Disadvantages |

| Expanded Polystyrene (EPS) | 0.038-0.042 | Class B | Cost-effective, easy installation | Residential buildings, standard facades | Flammable, requires fireproofing |

| Extruded Polystyrene (XPS) | 0.028-0.035 | Class B | Superior thermal performance, moisture resistance | Roof insulation, basements, humid environments | Weak adhesion, requires surface treatment |

| Rock Wool Board | 0.035-0.040 | Class A | Excellent fire resistance and sound insulation | High-rise buildings, fireproof facades | High water absorption, labor-intensive installation |

| Glass Wool | 0.036-0.042 | Class A1 | Non-combustible, superior acoustic insulation | Industrial buildings, stadiums | High hygroscopicity, health risks from dust |

| Polyurethane (PU) Board | 0.022-0.028 | Class B | Exceptional thermal insulation, waterproof | Energy-efficient buildings, roofs | Poor fire resistance, higher cost |

| Vacuum Insulation Panel (VIP) | 0.004-0.008 | Non-combustible | Ultra-low thermal conductivity, space-saving | Passive houses, ultra-low energy buildings | Expensive, prone to damage |

| Expanded Perlite Board | 0.045-0.060 | Class A | Superior fire resistance, eco-friendly | Fireproof facades | High water absorption, heavy weight |

| Glass Fiber Reinforced Board | 0.03-0.045 | Class A | High mechanical strength, fire resistance | Lightweight construction, external insulation systems | Brittle, complex installation |

| Phenolic Insulation Board | 0.022-0.028 | Class A | Excellent fire resistance, lightweight | Fireproof barriers, high-fire-rating facades | Brittle, moderate moisture resistance |

| Magnesium Oxide Board (MgO Board) | 0.065-0.08 | Class A | Fire-resistant, high strength, durable | Fireproof barriers, high-rise buildings, underground facilities | Moderate insulation performance, prone to moisture-related efflorescence |

What's The Best Insulation For Walls ?

Optimal Insulation for Home Walls

Selecting the best insulation for walls is crucial for comfort and energy efficiency. Whether you need insulation for exterior walls or internal dividers, understanding different materials and techniques is essential. We’ll compare top candidates for exterior wall insulation, evaluating their effectiveness in various scenarios.

Customizing Exterior Wall Insulation

Choosing the best exterior wall insulation depends on your specific situation: local climate, home design, budget, and long-term goals. Homeowners should work with an experienced installer who can recommend the best product for their needs.

Closed Cell Spray Foam Insulation

- Best Insulation for Walls: Closed cell spray foam insulation is renowned for its high R-value, which can reach up to R-7 per inch. It’s an ideal solution for creating an impermeable air seal, crucial in preventing energy leaks, making it one of the best insulation for outside walls.

- Best Exterior Wall Insulation: Its moisture-resistant properties and strength also contribute to its status as one of the best exterior insulation options, able to withstand the environmental stresses that exterior walls face.

Fiberglass Insulation

- Best Insulation for Walls: Fiberglass, particularly in batt form, is one of the most commonly used insulations due to its cost-effectiveness and ease of installation. With an R-value ranging from R-11 to R-15 for standard wall cavities, it’s a solid choice for interior and exterior wall insulation.

- Best Exterior Wall Insulation: When installed correctly, fiberglass batts can fill wall cavities completely, leaving no gaps, which makes it a contender for the best insulation for walls, balancing cost and performance.

Rigid Foam Insulation

When examining options for rigid foam insulation, two products that stand out for their unique properties and applications are phenolic foam boards and MGO (magnesium oxide) boards.

Phenolic Foam Boards

- Best Exterior Wall Insulation: Phenolic boards offer one of the highest R-values among rigid boards, typically between R-4 to R-7 per inch, making them a strong contender for the best exterior wall insulation. They are particularly effective in applications requiring both high thermal resistance and space conservation.

- Best Insulation for Walls: Due to their fire resistance and low smoke toxicity, phenolic foam boards are often chosen for buildings where safety is paramount, contributing to their status as some of the best insulation for walls in both residential and commercial construction.

MGO Boards

- Best Insulation for Outside Walls: While MGO boards themselves do not insulate, they are frequently used in exterior systems for their excellent fire resistance and as a protective layer over foam insulation. Their ability to withstand severe weather conditions also makes them a viable option for the best insulation for outside walls when used in conjunction with other insulative materials.

- Best Exterior Insulation: MGO boards complement other insulation types by enhancing durability and adding structural strength. This synergistic combination can often result in what many consider being the best exterior insulation system, offering both thermal efficiency and resilience.

Best Insulation For Exterior Walls

Insulation works is a complex and comprehensive system engineering. Excellent exterior wall insulation options can often reduce the cost of energy bills for homeowners by $2,000 to $8,000 per year.

The best insulation for walls is often affected by environmental factors and regulations, so not all high R-value materials can be used as exterior wall insulation materials.

If you are in Alaska or Norway, cold weather requires your insulation materials to have a higher thermal resistance (R-value), so you usually use:

Polyurethane foam: It has a very high thermal resistance (R-value) and can effectively keep warm.

Fiberglass: Fiberglass insulation is low-cost and easy to install. It is widely used for wall and roof insulation in residential and commercial buildings.

Rock wool: Mineral wool insulation provides high thermal resistance and good fire resistance.

Tropical climate (such as Thailand, Saudi Arabia)

Radiant barriers: such as reflective insulation films, can effectively reflect sunlight and reduce heat entry.

Lightweight concrete: Wall cavities have certain thermal insulation properties and are stable in high humidity environments.

White roof coating: reflects sunlight and reduces the amount of heat absorbed by the building.

High temperature and fire risk areas (such as California)

Rockwool: Excellent fire resistance, suitable for areas with high fire risk.

Gypsum board: Often used as a fire wall or fire barrier, it helps to slow the spread of fire.

Foam boards: Foam board insulation, such as mineral fiberboard, has good fire and thermal insulation properties.

Earthquake-prone areas

Flexible spray foam: such as elastic polyurethane foam, can absorb certain structural movements and reduce earthquake shock.

Fiberglass: has a certain degree of elasticity and can adapt to small movements of buildings.

Areas with strong regulatory restrictions (such as EU countries)

Wool insulation: natural material, environmentally friendly and recyclable, in line with strict environmental regulations.

Blockboard (OSB): commonly used for structural insulation, contains less harmful substances and adapts to strict environmental standards.

Interpreting Insulation: More Than R-Values

Understanding R-Values in Insulation

While R-values are crucial for measuring insulation’s ability to resist heat flow, they are just one factor. Effective insulation also involves humidity control, ease of installation, environmental impact, and long-term durability.

The Importance of R-Values

R-values are a key metric in thermal resistance, showing how well a material impedes heat flow. They are essential in the building and construction industry, providing a clear benchmark for insulation materials.

How R-Values Work

The concept is simple: a higher R-value means better insulative performance. When evaluating R-values, consider the specific conditions and locations where the insulation will be used, along with the heating and cooling system in the structure.

Typically, R-values are given for a one-inch thickness of material. For example, a material with an R-value of 5 means each inch of that material has five times the heat flow resistance of an inch of air.

Remember, R-values are cumulative. If you have two inches of material with an R-value of 5, the total R-value is 10.

R-values are critical in designing energy-efficient structures. They are a primary consideration when choosing insulation materials, highlighting their importance in sustainable building practices.

Fiberglass Insulation

Foam Board Insulation

Fiberglass Insulation by Owens Corning

Fiberglass insulation, made primarily of glass, is a key product from Owens Corning. It traps air to slow heat transfer, used in industries like automobiles and buildings for thermal insulation.

Technical Parameters of Fiberglass Insulation

Fiberglass insulation has a high R-value, typically ranging from 2.2 to 2.7 per inch. This indicates excellent thermal resistance, making it ideal for insulating buildings and vehicles. It comes in various forms, such as batt insulation and loose fill. Fiberglass batts are available in pre-cut panels and rolls, while loose fill is suitable for blowing machines. The thickness of the batts determines their R-value, with walls typically ranging from R11 to R19, and ceilings and attics reaching up to R30. Additionally, fiberglass insulation has low thermal conductivity, ensuring efficient heat retention and energy savings.

Cost of Installing Fiberglass Insulation

The cost of installing fiberglass insulation varies based on factors like the location of the house and the amount of labor required. On average, installation costs range from $0.88 to $1.64 per square foot. For a 500 square foot house, you could expect to pay between $300 and $600, including labor costs.

Summary

Fiberglass insulation from Owens Corning is a high-performance thermal insulation material, known for its ability to trap air and reduce heat transfer. With R-values ranging from 2.2 to 2.7 per inch, it’s available in batt and loose fill forms, catering to various insulation needs. Despite its effectiveness, installation costs can vary, averaging between $0.88 and $1.64 per square foot, making it an economical choice for enhancing energy efficiency in buildings.

The advantages of fiberglass insulation include

- Quick and easy installation: Especially when working with professionals, the installation process for fiberglass insulation is relatively quick and easy.

Affordability: Fiberglass insulation is one of the most cost-effective home insulation solutions.

Flexibility: With pre-cut panels, rolls, and loose fill options available, the installation of fiberglass insulation is incredibly flexible.

Energy efficiency: Fiberglass insulation can help reduce heating and cooling costs by 40% to 50%,this not only lowers utility bills but also reduces the carbon footprint of buildings.

Fire retardant: Fiberglass, made from recycled glass and sand, is a natural fire retardant, posing virtually no fire hazard.

Sound reduction: Fiberglass has natural sound-dampening properties, significantly reducing the amount of noise entering a home. This ability to reduce sound makes fiberglass a popular choice for insulation products.

Eco-friendly: Made from recycled materials, fiberglass is an environmentally conscious insulation alternative.

High R-Value: Fiberglass insulation has a high R-value, which means it provides excellent thermal resistance. This helps in keeping homes warm in the winter and cool in the summer, leading to significant energy savings.

Versatility: It comes in various forms, including batts and rolls for easy installation in standard-sized wall cavities and attics, as well as loose fill for irregular spaces. This versatility makes it suitable for a wide range of applications.

Durability: Fiberglass insulation does not degrade over time like some other materials. It maintains its R-value and effectiveness for many years, making it a durable choice for long-term insulation.

However, despite these advantages, there are some drawbacks to consider:

- Coverage: Since most fiberglass batts are pre-cut, installation can be challenging. Odd shapes, cracks, and other anomalies can pose challenges to standard-sized fiberglass batts.

Air leaks: Compared to other insulation materials like spray foam, fiberglass has a lower density and may not effectively prevent air leaks.

Moisture protection: In areas with high humidity, fiberglass offers less moisture protection. Leaks in the roof and dampness in attics and basements can contaminate fiberglass insulation and lead to mold issues.

Mold: Since fiberglass can retain moisture, it can create a thriving environment for mold spores.

Fiberglass insulation, is an affordable, environmentally friendly, and flexible insulation solution. However, when considering its use, potential issues such as installation challenges, air leaks, moisture, and mold protection should be factored in.

Foam board insulation has a high R-value and is good at preventing thermal bridging, making it an excellent choice for exterior walls.

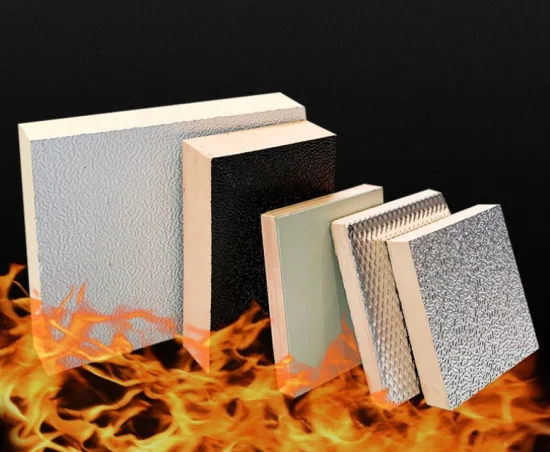

There’s a wide variety of foam insulation boards available on the market, with the most prevalent options being Phenolic Insulation Board (PF Board), Expanded Polystyrene (EPS Board), Extruded Polystyrene (XPS Board), and Polyisocyanurate (Polyiso Board).

Among these, the Phenolic Insulation Board stands out due to its superior R-value, a measure of thermal resistance. With an impressive R-value ranging from R-6 to R-8 per inch, the PF Board outperforms its EPS and XPS counterparts and is on par with, if not superior to, the Polyiso Board.

But the advantages of Phenolic Insulation Board don’t stop at thermal efficiency. It’s also renowned for its remarkable fire resistance, outshining the other three types of panels. Furthermore, when it comes to moisture resistance and dimensional stability, the PF Board holds the upper hand, making it a reliable choice in a variety of climates and conditions.

Most importantly, Phenolic Insulation Boards are champions of environmental sustainability. They boast a low Global Warming Potential (GWP) and an Ozone Depletion Potential (ODP) of zero, making them a truly eco-friendly insulation choice.

While the Phenolic Insulation Board may come with a higher price tag, its superior performance and environmental credentials make it a compelling choice for those seeking the best in insulation technology.

Pros: Excellent moisture resistance, ideal for wet climates. It is stiff and prevents sagging or settling. Certain types can also act as vapor barriers.

Cons: Some types may be flammable and may release toxic fumes when burned. Over time, it degrades if exposed to sunlight.

Foam Board Insulation for Exterior Walls

Foam board insulation has a high R-value and prevents thermal bridging, making it excellent for exterior walls.

Types of Foam Insulation Boards

There are various foam insulation boards available, including Phenolic Insulation Board (PF Board), Expanded Polystyrene (EPS Board), Extruded Polystyrene (XPS Board), and Polyisocyanurate (Polyiso Board).

Advantages of Phenolic Insulation Board

The Phenolic Insulation Board stands out with its superior R-value, ranging from R-6 to R-8 per inch. It outperforms EPS and XPS boards and is on par with, if not superior to, the Polyiso Board in thermal resistance.

Fire Resistance and Moisture Resistance

The PF Board is also known for its remarkable fire resistance and moisture resistance. It has excellent dimensional stability, making it reliable in various climates and conditions.

Environmental Sustainability

Phenolic Insulation Boards are champions of environmental sustainability. They have a low Global Warming Potential (GWP) and an Ozone Depletion Potential (ODP) of zero, making them eco-friendly.

Cost and Performance

While Phenolic Insulation Boards may be more expensive, their superior performance and environmental credentials make them a compelling choice for advanced insulation technology.

Pros and Cons

Pros: Excellent moisture resistance, ideal for wet climates. It is stiff and prevents sagging or settling. Certain types can also act as vapor barriers.

Cons: Some types may be flammable and may release toxic fumes when burned. Over time, it degrades if exposed to sunlight.

Beyond the Mainstream

Spray Foam Insulation: This insulation is applied in liquid form and expands on contact, filling gaps. Although expensive, it provides an excellent R-value and forms its own moisture barrier.

Cellulose Insulation: Made from recycled paper with fire protection treatment. Its dense composition gives it excellent noise reduction, but over time it settles.

Mineral Wool: This is a fire-resistant insulation that also offers good sound insulation.

Environmental and Financial Impact:

Both fiberglass and foam board insulation have their environmental footprints. Producing foam boards with ecologically conscious practices can reduce greenhouse gas emissions. However, both materials offer long-term energy savings that can offset their initial environmental costs.

Stay with Us: Pioneering Superior Insulation Performance

At the forefront of insulation technology, our products blend tradition and innovation. With unparalleled expertise, we promise not only quality products, but also instruction tailored to each homeowner’s unique situation.

Ready to embark on the journey to a warmer, more energy-efficient home? Work with our team for a total insulation consultation based on your unique requirements.

What is the R-value, and how does it affect insulation choice?

The R-value measures a material’s resistance to heat flow. Higher R-values mean better insulating properties. The best insulation for your exterior walls will have an R-value appropriate for your climate zone to ensure energy efficiency.

Is spray foam insulation the best option for exterior walls?

Spray foam insulation, particularly closed-cell spray foam, is often considered one of the best options because it fills cavities completely, air seals, and has a high R-value per inch. However, it is more expensive than other types of insulation.

what r value for exterior walls?

The R-value of exterior walls can vary widely depending on the materials used in construction, the climate zone the building is in, and the specific requirements of local building codes. The R-value is a measure of thermal resistance, indicating how well a material can prevent heat from escaping through the walls of a building.

- In the United States, the recommended R-values for exterior walls can range from R-13 to R-25 or higher, depending on the climate zone. For example:

- In warmer climates, where the primary concern is cooling rather than heating, walls might have an R-value of R-13 to R-15.

- In moderate climates, walls might have an R-value of R-19 to R-21.

- In colder climates, where heating is a significant concern, walls might have an R-value of R-21 to R-25 or even higher.

These values are typically achieved through a combination of insulation materials (such as fiberglass, cellulose, or rigid foam) and the thermal resistance of the wall structure itself (including framing and sheathing).

It’s important to note that building codes and energy efficiency standards are updated regularly, and the recommended R-values can change. For the most accurate and up-to-date information, it’s best to consult the local building codes or the International Energy Conservation Code (IECC) for the specific requirements in your area.