R Value measures an insulation material’s resistance to heat flow — the higher the R Value, the better the insulation effectiveness. It is expressed in (ft²·°F·h)/BTU, a standardized unit defined by ASTM C168 and widely used in U.S. building codes.

Proper insulation is critical for energy efficiency. According to the U.S. Energy Information Administration (EIA), heating and cooling account for over 50% of residential energy use. Poor insulation installed without proper attention to air seal and thermal resistance can lead to 25%–30% heat losses through exterior walls, roofs, and floors — increasing both costs and emissions.

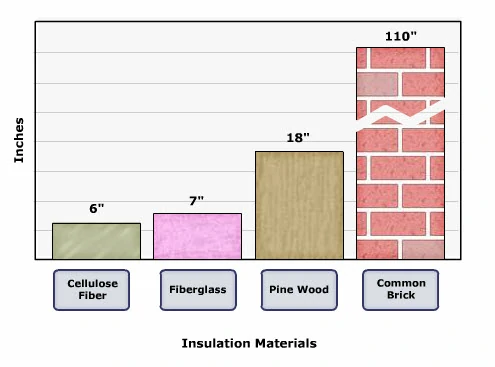

Different types of insulation offer different R Values per inch:

Fiberglass batts: R-3.1 to R-3.8

Extruded polystyrene (XPS): around R-5

Polyisocyanurate (PIR): up to R-6.5

Closed cell spray foam insulation: R-6.0 to R-7.0

Understanding R Value helps builders, architects, and homeowners select the right insulation material for specific climate zones and code requirements. In this article, we’ll break down what R Value means, how it’s measured, and why it’s central to every insulation product decision.

How Is R Value Defined?

R Value is the measure of thermal resistance across an insulation material. It indicates how effectively an insulation material resists resistance to heat flow — the higher the R Value, the better the insulation effectiveness.

R Value is calculated as:

R=ΔTQ/AR = \frac{\Delta T}{Q/A}R=Q/AΔT

where:

RRR = thermal resistance in (ft²·°F·h)/BTU

ΔT\Delta TΔT = temperature difference across the material (°F)

QQQ = heat flow rate (BTU per hour)

AAA = heat transfer area (ft²)

By definition, R Value is the reciprocal of thermal conductance (C Value). This relationship allows direct comparison between different types of insulation and thicknesses.

R Value measurement is standardized through ASTM C168, with common testing methods including:

ASTM C518 (Heat Flow Meter for insulation products)

ASTM C1363 (Guarded Hot Box for larger building assemblies)

ASTM C177 (Guarded Hot Plate method)

These tests ensure consistent evaluation of thermal resistance under controlled conditions, including material thickness, temperature gradient, and moisture content.

The use of R Value became mandatory in the U.S. following the 1970s energy crisis, when the Federal Trade Commission (FTC) introduced labeling regulations under the Home Insulation Rule (16 CFR Part 460). This standardization helps builders, architects, and consumers make informed decisions based on reliable thermal performance data for insulation products used across various climate zones.

How to Select the Right R Value for Your Project

Choosing the appropriate R Value requires evaluating the climate zone, building type, assembly conditions, and performance objectives. While insulation requirements are defined by codes such as the International Energy Conservation Code (IECC), the U.S. Department of Energy (DOE) guidelines, and ASHRAE Standard 90.1 for commercial buildings, the optimal choice often exceeds these baselines to achieve better energy efficiency and long-term value.

Key Considerations for R Value Selection

Project Type and Assembly Constraints

New Construction vs. Retrofit: Existing buildings may have space limitations that restrict insulation thickness, requiring higher-performance insulation materials such as closed cell spray foam insulation.

Assembly Type: Roof assemblies, wall cavities, and foundation elements have different resistance to heat flow characteristics. For example, exterior walls with wood framing are prone to thermal bridging, making continuous insulation (ci) an effective strategy.

Climate Zone Requirements

The IECC defines 8 climate zones across the U.S., each with specific R Value recommendations based on heating and cooling demands. Higher R Values are required in colder zones (Zone 6–8), while moderate zones (Zone 3–5) allow for mid-range values.

| Building Element | IECC Recommended R Value (Example: Zone 5) |

| Attic / Roof Assembly | R-49 |

| Exterior Walls | R-20 cavity or R-13 cavity + R-5 continuous |

| Floors over Unconditioned Space | R-30 |

| Slab Edge (Unheated) | R-10 (2 ft depth) |

| Basement Walls | R-15 continuous or R-19 cavity |

Type of Insulation Material

Match the appropriate type of insulation to the assembly design and installation conditions:Fiberglass batts: Common in wall cavities, R-3.1 to R-3.8 per inch

Loose fill fiberglass or cellulose: Ideal for attic spaces and irregular areas

Rigid foam boards (XPS, PIR): For continuous insulation, R-5 to R-6.5 per inch

Closed cell spray foam insulation: Up to R-7 per inch, providing both thermal resistance and effective air seal where space is limited

Thermal Bridging and Air Sealing

Framing members and penetrations reduce effective R Value due to thermal bridging. Use continuous insulation or insulated sheathing to mitigate these heat losses. Combine insulation with proper air seal techniques to prevent uncontrolled airflow, which can significantly reduce insulation effectiveness.Installation Quality

Proper installation of insulation products is critical. Compression, voids, or moisture intrusion can degrade actual performance, regardless of rated R Value. Following manufacturer guidelines and industry best practices ensures that the specified thermal resistance is achieved.

By balancing these factors — climate zone, assembly design, insulation material choice, and installation quality — project teams can select insulation systems that not only meet code requirements but also optimize energy efficiency and occupant comfort.