Explanation of phenolic insulation

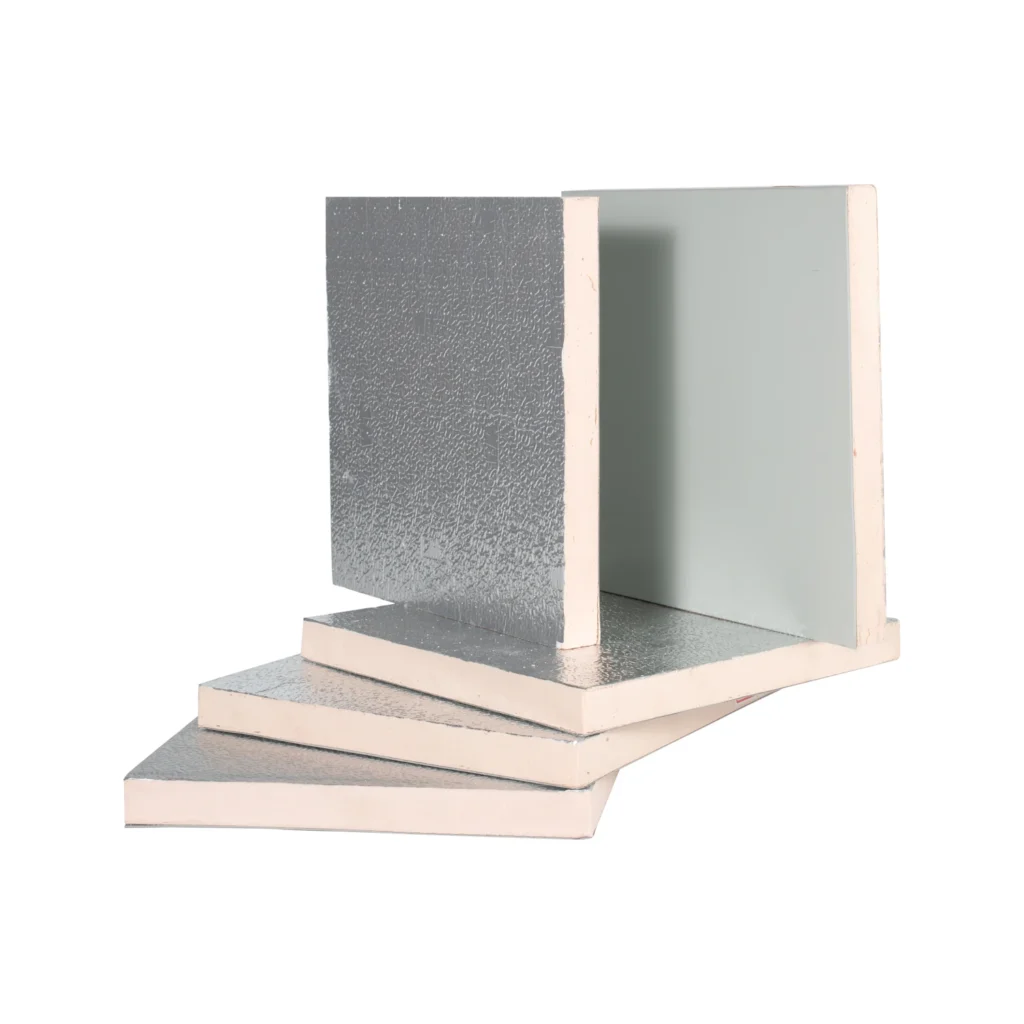

Phenolic insulation stands as a premier choice in the insulation industry, known for its exceptional thermal performance and fire-resistant properties. This versatile material is crafted from phenolic foam, a high-performance insulation product that boasts an impressive R-value, indicating superior resistance to heat flow. Phenolic foam insulation is not only effective in maintaining temperature but also provides a robust solution for fire safety, meeting stringent industry standards for flame spread and smoke development.

In applications such as pipe insulation, phenolic foam pipe insulation offers a durable and efficient way to reduce heat loss and prevent condensation, making it ideal for both hot and cold piping systems. Similarly, in ductwork, phenolic duct insulation helps to maintain air temperatures, improving energy efficiency and comfort in HVAC systems.

Technical data supports the efficacy of phenolic insulation, with studies showing its low thermal conductivity and high resistance to moisture absorption. For instance, phenolic insulation has a typical thermal conductivity of around 0.02 W/m·K, which is significantly lower than many other insulation materials. This means that phenolic insulation can achieve the same level of thermal resistance with a thinner profile, saving space and material costs.

Moreover, phenolic insulation is known for its long-term stability and resistance to aging, ensuring that its performance remains consistent over time. This durability, combined with its environmental benefits—such as low embodied energy and recyclability—makes phenolic insulation a sustainable choice for building and industrial applications.

View our products: Phenolic Insulation

Importance of phenolic insulation in various industries

Within the industrial sector, phenolic pipe insulation is indispensable. It safeguards pipelines against thermal losses and gains, ensuring the integrity of process fluids and gases. The insulation’s low thermal conductivity—often around 0.02 W/m·K—minimizes energy waste in piping systems, contributing to operational efficiency.

Phenolic ductwork further demonstrates the material’s versatility. In HVAC systems, phenolic duct insulation maintains air temperatures, reducing the load on heating and cooling equipment. This not only conserves energy but also enhances indoor air quality by minimizing the formation of condensation, which can foster mold growth.

Technical data underscores the importance of phenolic insulation. For example, its high-temperature stability allows it to perform reliably in environments where other insulation materials may degrade. Additionally, phenolic insulation’s resistance to water vapor diffusion helps protect against corrosion in metal pipes and ducts, extending the lifespan of these components.

In the transportation industry, phenolic foam’s lightweight yet robust nature makes it suitable for insulating vehicles and vessels. It contributes to fuel efficiency by reducing the energy required for climate control, a benefit that resonates with the growing emphasis on sustainability.

Overall, the data-backed performance of phenolic insulation aligns with the industries’ needs for cost-effective, energy-efficient, and safe insulation solutions. Its widespread application is a testament to its critical role in meeting the challenges of modern industrial and construction practices.

Composition and Properties of Phenolic Insulation

At the heart of phenolic insulation is phenolic foam, a material composed of phenol, formaldehyde, and a blowing agent. This combination expands into a rigid, closed-cell structure, which is the secret behind its impressive insulation properties.

Phenolic foam insulation boasts a low thermal conductivity, typically around 0.02 W/m·K. This results in a high R-value, providing superior resistance to heat transfer. For example, a 1-inch thick board of phenolic foam can achieve an R-value of about 5, outperforming many other insulation materials of equal thickness.

Fire safety is a critical aspect where phenolic insulation excels. It is naturally flame-retardant and meets rigorous safety standards, such as those outlined in ASTM E84. This makes it an ideal choice for insulating buildings and industrial settings where fire resistance is paramount.

Moisture is no match for phenolic insulation. Its closed-cell structure repels water vapor, inhibiting the growth of mold and mildew. This moisture resistance enhances the durability of the insulation, ensuring it maintains its performance over time with minimal maintenance.

Environmentally, phenolic insulation is a step ahead. Its high R-value means less material is required for effective insulation, reducing waste. Furthermore, phenolic foam is derived from renewable resources and is recyclable, supporting sustainability efforts.

In essence, the composition and properties of phenolic insulation—its low thermal conductivity, high R-value, fire resistance, moisture resistance, durability, and environmental benefits—make it a top-tier choice for various insulation needs.

Materials used in phenolic insulation

Phenolic insulation is derived from a specialized combination of materials that are integral to its performance. The core material is phenolic foam, which is synthesized through a chemical reaction involving phenol and formaldehyde, along with a blowing agent. This process creates a rigid, closed-cell structure that is the foundation of phenolic foam insulation.

The blowing agent used in the production of phenolic foam is crucial for achieving the desired expansion and cellular structure. It helps to create a matrix of tiny cells filled with gas, which contributes to the material’s low density and high insulation properties.

For applications such as pipe insulation, the phenolic foam is often reinforced with a glass fiber scrim or other materials to enhance its mechanical strength and durability. This reinforcement is particularly important in phenolic pipe insulation, where the insulation must withstand potential impacts and vibrations without compromising its thermal efficiency.

In ductwork, phenolic duct insulation may also incorporate facing materials that provide additional protection against moisture and mechanical damage. These facings can be made from aluminum foil, glass cloth, or other reinforcing materials, tailored to the specific requirements of the duct system.

Throughout its composition, phenolic insulation benefits from the precise selection and combination of materials, ensuring that it delivers superior thermal performance, fire resistance, and durability. The use of renewable resources and recyclable materials in its production further underscores its environmental responsibility.

Thermal Conductivity and R-Value of Phenolic Insulation

Phenolic insulation is renowned for its exceptional thermal properties, which are quantified by its low thermal conductivity and high R-value. The thermal conductivity of phenolic foam typically ranges from 0.018 to 0.023 W/m·K, making it one of the most effective insulating materials available. This low conductivity means that phenolic foam insulation can significantly reduce the flow of heat through walls, roofs, pipes, and ductwork.

The R-value is a measure of a material’s thermal resistance, indicating its ability to prevent heat from transferring between indoor and outdoor environments. Phenolic foam insulation has an R-value that is generally higher than that of other traditional insulation materials. For instance, a 1-inch thick phenolic foam board can have an R-value of approximately 5 to 6, depending on the specific formulation and density.

In the context of phenolic pipe insulation, the high R-value is particularly beneficial for maintaining process temperatures and preventing heat loss or gain. This not only conserves energy but also ensures that the contents of the pipes remain within the required temperature range, which is critical for many industrial applications.

For phenolic duct insulation, the superior R-value contributes to the energy efficiency of HVAC systems by minimizing the thermal exchange between the conditioned air inside the ducts and the ambient environment outside. This helps to reduce the load on heating and cooling equipment, leading to lower energy consumption and costs.

Fire resistance and safety standards

Phenolic insulation is distinguished by its inherent fire resistance, a critical feature that enhances safety in various applications. Phenolic foam, the base material of phenolic insulation, is naturally flame-retardant due to its chemical composition. This means that it not only resists ignition but also limits the spread of flames if a fire were to occur.

The fire performance of phenolic insulation is measured against stringent safety standards. One such standard is the ASTM E84 test, which assesses the surface burning characteristics of building materials. Phenolic foam typically achieves a flame spread index of less than 25 and a smoke-developed index of less than 450, classifying it as a low-smoke, low-flame-spread material.

In the context of phenolic pipe insulation, this fire resistance is particularly valuable for industrial settings where the risk of fire is heightened. The insulation helps to contain the spread of flames along the piping network, providing a safer environment for workers and protecting equipment from damage.

For phenolic ductwork, the fire-resistant properties are equally important. In the event of a fire, the insulation can help prevent the ducts from becoming conduits for flame and smoke propagation, aiding in the compartmentalization of fire and reducing the overall risk to the building and its occupants.

Moreover, phenolic insulation does not contain chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs), which can contribute to the production of toxic gases when exposed to high temperatures. This makes phenolic foam insulation a safer choice from an environmental and health standpoint during a fire event.

Moisture resistance and durability

Phenolic insulation exhibits outstanding moisture resistance, a trait that is essential for maintaining its performance over time. The closed-cell structure of phenolic foam creates an effective barrier against water vapor diffusion, preventing the absorption of moisture. This resistance to moisture is critical in environments where condensation or water exposure is a concern.

The low water absorption rate of phenolic foam insulation typically ranges from 1% to 3% by volume, even after prolonged exposure to water. This low rate ensures that the insulation’s thermal properties remain consistent, as the accumulation of moisture can significantly reduce the effectiveness of other insulation materials.

In the realm of phenolic pipe insulation, moisture resistance is particularly beneficial. It protects the piping system from corrosion and degradation, which can be caused by the ingress of moisture. This protection extends the lifespan of both the insulation and the pipe, reducing the need for maintenance and replacement.

For phenolic ductwork, moisture resistance is equally important. It helps to prevent the growth of mold and mildew within the ducts, which can compromise indoor air quality. By maintaining a dry interior, phenolic duct insulation contributes to a healthier environment and reduces the potential for respiratory issues associated with poor air quality.

The durability of phenolic insulation is further enhanced by its resistance to aging and environmental factors. It maintains its structural integrity and thermal efficiency even in challenging conditions, such as extreme temperatures or exposure to UV light.

Environmental benefits and sustainability

Phenolic insulation offers a range of environmental benefits that align with sustainability goals. Its high R-value means that less material is needed to achieve the desired level of insulation, reducing the demand for raw materials and the associated environmental impact of production and transportation.

Phenolic foam is manufactured without ozone-depleting substances such as chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs). This is in compliance with the Montreal Protocol, an international treaty designed to protect the ozone layer. The absence of these harmful chemicals in phenolic insulation supports efforts to reduce global warming and climate change.

In terms of end-of-life management, phenolic foam insulation is recyclable. This means that it can be processed at the end of its service life to create new insulation products or other materials, reducing waste and conserving resources. The recyclability of phenolic insulation contributes to a circular economy, where materials are reused and recycled to minimize environmental impact.

Moreover, the energy savings achieved through the use of phenolic insulation can lead to a reduction in greenhouse gas emissions. By improving the energy efficiency of buildings and industrial processes, phenolic insulation helps to lower the carbon footprint associated with heating and cooling.

In applications like phenolic pipe insulation and phenolic ductwork, the longevity and durability of the material mean that it requires less frequent replacement. This not only saves resources but also reduces the energy and emissions associated with the manufacturing and installation of new insulation materials.

Applications of Phenolic Insulation

Phenolic insulation is a versatile material that finds applications across various industries due to its unique combination of thermal efficiency, fire resistance, and durability. In the construction sector, phenolic foam insulation is used in walls, roofs, and floors to enhance the energy efficiency of buildings. Its high R-value per inch makes it an effective choice for both new construction and retrofit projects, helping to reduce heating and cooling costs.

Building and Construction Industry

- Wall and Roof Insulation:Phenolic insulation is widely used in the building and construction industry for wall and roof insulation. Its high R-value makes it an excellent choice for enhancing the thermal performance of buildings, reducing energy consumption for heating and cooling. Phenolic foam insulation can be easily integrated into new constructions or used for retrofitting existing structures, providing a cost-effective solution for improving energy efficiency.

- HVAC Systems:In HVAC systems, phenolic duct insulation is crucial for maintaining the temperature of the air as it travels through the ductwork. This insulation helps to reduce heat loss or gain, ensuring that the conditioned air reaches the occupied spaces without significant thermal degradation. This application of phenolic insulation contributes to the overall energy efficiency of the building’s climate control system.

Learn More About:Is Your Building Protected?

Industrial Applications

- Pipeline Insulation:Phenolic pipe insulation is a critical component in industrial applications where pipelines transport fluids or gases at specific temperatures. This insulation helps to maintain the temperature of the contents, preventing energy loss and ensuring that the materials remain within the required thermal parameters. Phenolic foam pipe insulation is particularly effective in harsh environments due to its durability and resistance to moisture and chemicals.

- Cold Storage and Refrigeration:In cold storage facilities and refrigeration units, phenolic insulation is used to maintain low temperatures, preserving the quality of perishable goods. Its low thermal conductivity and resistance to moisture make it an ideal choice for walls, floors, and roofs in these settings. Phenolic insulation helps to reduce energy consumption by minimizing the transfer of heat into the refrigerated spaces.

Marine and Transportation Sectors

- Insulation for Vehicles and Vessels:Phenolic insulation is also employed in the marine and transportation sectors to insulate vehicles and vessels. It helps to regulate the temperature inside cabins and cargo areas, improving comfort for passengers and crew while protecting sensitive cargo. Phenolic foam’s lightweight nature is particularly beneficial for vehicles and vessels, where reducing weight can lead to better fuel efficiency.

- Thermal Protection in Engines and Machinery:In engines and machinery, phenolic insulation provides thermal protection, shielding sensitive components from excessive heat. This can help to extend the lifespan of equipment by preventing overheating and reducing the risk of failure. Phenolic insulation’s ability to withstand high temperatures makes it suitable for use in a variety of mechanical applications where thermal management is critical.

Benefits of WT's Phenolic Insulation

- High-quality Manufacturing Process:WT’s phenolic insulation is the result of a high-quality manufacturing process that ensures consistency and reliability. The production of phenolic foam involves precise control over the expansion and curing of the material, leading to a uniform cell structure that optimizes thermal performance. This meticulous process guarantees that WT’s insulation products meet the highest standards of quality and performance.

- Compliance with Industry Standards and Certifications:WT’s phenolic insulation adheres to industry standards and has obtained relevant certifications, providing assurance of its quality and safety. Compliance with standards such as ASTM E84 for fire resistance and ASTM C518 for thermal conductivity demonstrates WT’s commitment to meeting or exceeding the benchmarks set by the insulation industry. These certifications make WT’s insulation a trusted choice for contractors and building owners.

- Customization Options for Various Applications:WT offers customization options for its phenolic insulation, allowing it to be tailored to the specific needs of different applications. Whether it’s for wall and roof insulation, HVAC ductwork, or industrial piping, WT can provide insulation solutions that are cut to size, faced with appropriate materials, or enhanced with additional layers for improved performance. This flexibility ensures that WT’s insulation can be integrated seamlessly into various construction and industrial projects.

- Cost-effectiveness and Return on Investment:Investing in WT’s phenolic insulation is a cost-effective choice in the long run. Despite the initial cost, the energy savings achieved through reduced heating and cooling requirements can lead to a significant return on investment. The durability and longevity of phenolic insulation mean that it requires less maintenance and replacement over time, further enhancing its cost-effectiveness.

- Contribution to Energy Efficiency and Reduced Carbon Footprint:WT’s phenolic insulation plays a vital role in enhancing energy efficiency in buildings and industrial processes. By minimizing heat transfer, it helps to reduce the energy consumption associated with heating and cooling, leading to lower utility bills and a reduced carbon footprint. This contribution to sustainability aligns with global efforts to combat climate change and promote environmentally responsible construction and operation practices.

Learn More About:Maximizing Energy Efficiency with Phenolic Insulation

Your questions answered

FAQs about Phenolic Insulation

How does phenolic insulation compare to other insulation materials?

Phenolic insulation compares favorably to other insulation materials across several key metrics. Here’s how it stacks up:

- Thermal Performance: Phenolic foam insulation boasts a higher R-value per inch than many other insulation materials, such as fiberglass or rock wool. This means it provides superior thermal resistance, making it more effective at preventing heat transfer.

- Fire Resistance: Phenolic insulation is inherently flame-retardant and performs well in fire tests, often exceeding the fire safety ratings of other materials. It is less likely to contribute to the spread of flames or the production of smoke.

- Moisture Resistance: With its closed-cell structure, phenolic foam has a low water absorption rate, making it highly resistant to moisture. This is advantageous in environments where humidity or water exposure is a concern, as it maintains its insulating properties even when wet.

- Durability: Phenolic insulation is known for its durability and longevity. It is resistant to aging, UV light, and environmental stresses, ensuring that it maintains its effectiveness over time.

- Environmental Impact: Phenolic insulation is manufactured without ozone-depleting substances and is recyclable, giving it an edge in terms of environmental sustainability compared to some other insulation materials.

- Cost: While the initial cost of phenolic insulation may be higher than some alternatives, its superior performance and durability can lead to long-term cost savings through reduced energy consumption and maintenance.

In summary, phenolic insulation offers a combination of high thermal performance, fire resistance, moisture resistance, durability, and environmental benefits. While it may come at a higher upfront cost, its overall value and contribution to energy efficiency make it a competitive choice in the insulation market.

Can phenolic insulation be used in both new construction and retrofits?

Yes, phenolic insulation can be used in both new construction and retrofit projects. Its versatility allows it to be integrated into the building envelope during the initial construction phase or applied as part of an energy-efficiency upgrade for existing structures. In new construction, phenolic insulation can be easily incorporated into walls, roofs, and floors to enhance the thermal performance of the building from the outset. For retrofits, it can be added to improve insulation without necessarily requiring major modifications to the existing structure, making it a practical choice for upgrading the energy efficiency of older buildings.

Is phenolic insulation easy to install?

Yes, phenolic insulation is generally easy to install, making it a practical choice for both professional contractors and do-it-yourself enthusiasts. The insulation typically comes in pre-cut panels or boards that can be easily fitted into place. For wall and roof applications, the panels are often secured with adhesives or mechanical fasteners, depending on the specific requirements of the project.

For pipe and duct insulation, phenolic foam can be supplied in sheet form or as pre-formed sections that fit snugly around the piping or ductwork. This design allows for a quick and efficient installation process, minimizing downtime in operational settings.

Additionally, the lightweight nature of phenolic insulation makes it easier to handle and install compared to denser materials. The simplicity of the installation process contributes to its popularity among builders and renovators looking for effective insulation solutions that are user-friendly.

What are the maintenance requirements for phenolic insulation?

Phenolic insulation is known for its low maintenance requirements, which is one of its advantages over some other insulation materials. Due to its durability and resistance to moisture, pests, and mold, phenolic insulation typically does not require frequent upkeep. Here are a few points regarding its maintenance:

- Longevity: Phenolic insulation has a long service life, often lasting for many years without degradation in performance. This means that once installed, it does not need to be replaced as often as other types of insulation.

- Inspection: Periodic inspections are recommended to ensure that the insulation remains intact and has not been damaged by external factors such as physical impact or exposure to elements. Checking for any signs of wear or deterioration can help maintain the effectiveness of the insulation.

- Cleaning: In most cases, phenolic insulation does not require cleaning. However, if dust or debris accumulates on the surface in accessible areas, it can be gently removed to maintain a clean environment.

- Protection: It’s important to protect the insulation from mechanical damage, which could compromise its performance. In areas prone to impact, additional protective layers or covers may be applied.

- Sealing: Ensuring that all joints and edges are properly sealed can prevent the ingress of moisture or pests. Any damage to the sealant should be repaired promptly.

Overall, the maintenance of phenolic insulation is minimal, especially when compared to insulation materials that are more susceptible to environmental factors. Its resistance to common issues such as moisture absorption and mold growth reduces the need for regular maintenance, making it a cost-effective and reliable insulation solution.

How long does phenolic insulation last?

Phenolic insulation is known for its durability and can last for an extended period, often exceeding 20 years, depending on the specific application and the conditions to which it is exposed. Its longevity is attributed to its resistance to moisture, mold, pests, and the general wear and tear that other insulation materials may succumb to over time. However, the lifespan of phenolic insulation can vary based on factors such as the quality of the material, the installation process, and the environmental conditions it faces. Regular inspections and proper maintenance can help ensure that phenolic insulation performs optimally throughout its expected service life.

If you have any further questions about phenolic insulation, please feel free to contact us, and we will provide professional answers.

sales@wtinsulation.com

Phone

0086-13771601681

Address

No.5,North Waihuan Road,Huangtang Industrial Zone, Xuxiake Town, JiangYin City, Jiangsu Province, China