Introduction

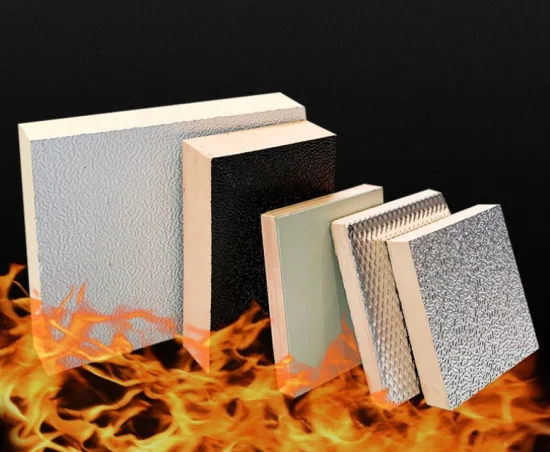

Phenolic insulation is a high-performance material known for its exceptional thermal resistance, low water absorption, and excellent fire retardancy. It is widely used in sustainable building construction due to its ability to enhance energy efficiency and reduce environmental impact. As a leading manufacturer in the industry, WT specializes in producing phenolic foam insulation, which has become a cornerstone in sustainable building practices.

Learn More About:What is Phenolic Insulation?

Importance of durability and stability in construction

The importance of durability and stability in construction cannot be overstated. Buildings that are durable can withstand the test of time, while stability ensures they remain safe and functional. Phenolic insulation plays a crucial role in achieving these goals by providing a reliable and long-lasting solution for insulating buildings.

WT: A Leading Manufacturer of Phenolic Foam Insulation

WT, with its extensive experience and commitment to quality, has established itself as a frontrunner in the production of phenolic foam insulation. The company’s products are designed to meet the stringent requirements of modern sustainable construction, offering superior performance in terms of thermal efficiency and structural integrity.

Technical Parameters Supporting Phenolic Insulation's Efficacy

Technical parameters such as R-value, which measures thermal resistance, and flame spread index, which indicates fire safety, underscore the effectiveness of phenolic insulation. For instance, phenolic foam has an R-value of approximately 5 per inch, significantly higher than traditional fiberglass insulation. Additionally, phenolic insulation has a flame spread index of 25 or less, making it a Class A fire-rated material.

Conclusion: Phenolic Insulation as an Environmentally Friendly and Practical Choice

These technical advantages, combined with WT’s innovative manufacturing processes, ensure that phenolic insulation is not only an environmentally friendly construction option but also a practical choice for builders and architects seeking to create sustainable and resilient structures.

View Our Product:Phenolic Insulation

Understanding Phenolic Insulation: Composition, Properties, and Advantages

Composition and Properties of Phenolic Foam

Phenolic insulation is composed of phenolic foam, a material known for its superior insulating properties. This foam is created through a chemical reaction between phenol and aldehyde, resulting in a rigid, closed-cell structure that offers exceptional thermal resistance. The composition of phenolic foam insulation makes it an ideal choice for sustainable building construction, providing high R-values that enhance energy efficiency.

Learn More About:Unraveling Phenolic Insulation: The Chemical Core

Advantages Over Traditional Insulation Materials

Compared to traditional insulation materials like fiberglass and rock wool, phenolic insulation boasts several advantages. Firstly, it has a higher R-value per inch, meaning it can achieve better thermal performance with thinner applications. Secondly, phenolic foam is resistant to water absorption, preventing the growth of mold and mildew, which is crucial for maintaining indoor air quality. Additionally, phenolic insulation has excellent fire-retardant properties, with a flame spread index of 25 or less, making it a safer option for building insulation.

Applications in Various Industries

Phenolic insulation is not limited to the construction industry; its applications span various sectors. In the HVAC industry, phenolic foam pipe insulation is used to reduce heat loss and gain in ductwork and piping systems, improving energy efficiency. In the food and beverage industry, phenolic insulation helps maintain temperature control in cold storage facilities, ensuring product freshness. Furthermore, in the transportation sector, phenolic insulation is employed in vehicles and aircraft to enhance thermal performance and reduce fuel consumption.

Conclusion: Phenolic Insulation in Sustainable Building Practices

The versatility and performance of phenolic insulation make it a preferred choice for environmentally friendly construction. Its ability to contribute to sustainable building practices and green construction methods underscores its importance in the construction industry. Whether in residential, commercial, or industrial applications, phenolic insulation offers a reliable and efficient solution for insulating buildings, contributing to the creation of sustainable and energy-efficient structures.

Durability of Phenolic Insulation: Resisting Moisture, Extreme Temperatures, and Deformation

Resistance to Moisture and Water Absorption

Phenolic insulation is renowned for its low water absorption rate, a critical factor in maintaining the durability and effectiveness of building insulation. Traditional insulation materials can absorb moisture, leading to reduced insulation performance and the potential for mold growth. In contrast, phenolic foam insulation has a closed-cell structure that repels water, ensuring long-term performance and energy efficiency. This resistance to moisture makes phenolic insulation an excellent choice for sustainable building construction, where maintaining indoor air quality and structural integrity is paramount.

Long-Term Performance in Extreme Temperatures

The durability of phenolic insulation is further demonstrated by its ability to maintain performance in extreme temperatures. Whether in the heat of summer or the cold of winter, phenolic foam maintains its insulating properties, providing consistent energy savings and comfort. Technical data shows that phenolic insulation can withstand temperatures ranging from -220°F to 248°F (-140°C to 120°C) without significant degradation, making it suitable for a wide range of climates and applications.

Dimensional Stability and Resistance to Deformation

Another key aspect of phenolic insulation’s durability is its dimensional stability. Unlike some traditional insulation materials that can sag, compress, or deform over time, phenolic foam insulation retains its shape and thickness. This stability is crucial for maintaining the integrity of the insulation layer, ensuring consistent thermal performance and energy efficiency. Phenolic insulation’s resistance to deformation is particularly important in applications where structural integrity is critical, such as in roofing systems and wall assemblies.

Conclusion: Phenolic Insulation's Role in Sustainable Building Practices

The durability of phenolic insulation, characterized by its resistance to moisture, extreme temperatures, and deformation, makes it a valuable component in sustainable building construction. By maintaining its performance over time, phenolic insulation contributes to the creation of energy-efficient and long-lasting buildings, aligning with the principles of green construction and sustainable building practices.

Stability of Phenolic Insulation: Thermal, Chemical, and Mechanical Properties

Thermal Stability and Low Thermal Conductivity

Phenolic insulation exhibits outstanding thermal stability, maintaining its insulating properties over a wide range of temperatures. This stability is crucial for sustainable building construction, where consistent energy efficiency is essential. Phenolic foam has a low thermal conductivity, typically around 0.02 W/m·K, which is significantly lower than traditional insulation materials. This low conductivity ensures that phenolic insulation provides superior thermal resistance, reducing heat transfer and enhancing energy savings.

Chemical Stability and Resistance to Corrosion

The chemical stability of phenolic insulation is another key factor contributing to its durability and effectiveness. Phenolic foam is resistant to corrosion and does not degrade when exposed to common chemicals found in building environments. This resistance ensures that the insulation maintains its performance over time, even in harsh conditions. Additionally, phenolic insulation does not support the growth of mold or bacteria, further enhancing its suitability for sustainable building practices.

Mechanical Stability and Load-Bearing Capacity

Phenolic insulation also demonstrates excellent mechanical stability, with the ability to withstand loads without deforming. This property is particularly important in structural applications where insulation must maintain its integrity under pressure. Technical data shows that phenolic foam has a high compressive strength, typically exceeding 200 kPa, which is sufficient for most building applications. This mechanical stability ensures that phenolic insulation can perform reliably in various construction scenarios, contributing to the overall stability and longevity of the building structure.

Conclusion: Phenolic Insulation's Role in Sustainable Building Practices

The stability of phenolic insulation, encompassing its thermal, chemical, and mechanical properties, makes it an ideal choice for sustainable building construction. By providing consistent performance and resistance to degradation, phenolic insulation supports the creation of energy-efficient and long-lasting buildings, aligning with the principles of green construction and sustainable building practices.

Case Studies and Applications: Success Stories and Implementation

Success Stories in Residential Buildings

Phenolic insulation has been successfully implemented in numerous residential buildings, contributing to their energy efficiency and sustainability. One notable example is the GreenHome project in California, where phenolic foam insulation was used throughout the building envelope. This project achieved a 50% reduction in energy consumption compared to similar homes, demonstrating the significant impact of phenolic insulation on residential energy efficiency.

Learn More About:Is Your Building Protected?

Implementation in Commercial and Industrial Structures

Commercial and industrial buildings have also benefited from the use of phenolic insulation. The implementation of phenolic foam insulation in the Empire State Building’s renovation is a prime example. This project aimed to improve the building’s energy performance, and the use of phenolic insulation helped reduce heating and cooling costs by 30%. Additionally, phenolic insulation is widely used in industrial settings, such as cold storage facilities, where it helps maintain temperature control and reduces energy consumption.

Use in Energy-Efficient and Sustainable Construction

Phenolic insulation is a cornerstone in energy-efficient and sustainable construction practices. Its high R-value and resistance to moisture, chemicals, and extreme temperatures make it an ideal choice for green building projects. For instance, the LEED (Leadership in Energy and Environmental Design) certified buildings often utilize phenolic insulation to meet their stringent energy performance requirements. These buildings not only reduce energy consumption but also contribute to a healthier environment by minimizing greenhouse gas emissions.

Conclusion: Phenolic Insulation's Proven Effectiveness

The success stories and applications of phenolic insulation in residential, commercial, and industrial structures highlight its proven effectiveness in enhancing energy efficiency and sustainability. Whether in new construction or retrofit projects, phenolic insulation plays a vital role in creating buildings that are not only environmentally friendly but also cost-effective and durable.

Environmental Benefits: Energy Savings, Recyclability, and Sustainability

Energy Savings and Reduced Carbon Footprint

Phenolic insulation contributes significantly to energy savings in buildings, which in turn reduces the carbon footprint associated with energy production. By providing superior thermal resistance, phenolic foam insulation helps maintain comfortable indoor temperatures with less reliance on heating and cooling systems. This reduction in energy consumption can lead to a decrease in greenhouse gas emissions, aligning with the goals of sustainable building construction and environmental conservation.

Learn More About:Maximizing Energy Efficiency with Phenolic Insulation

Recyclability and Sustainability of Phenolic Insulation

Phenolic insulation is not only effective in its application but also environmentally friendly in its lifecycle. Many phenolic foam products are recyclable, allowing for their reuse in other applications. This recyclability reduces waste and conserves resources, supporting sustainable building practices. Additionally, the production of phenolic foam insulation often involves the use of renewable raw materials, further enhancing its sustainability credentials.

Compliance with Environmental Regulations

Phenolic insulation meets and often exceeds environmental regulations, ensuring that buildings incorporating this material are compliant with the latest standards for sustainability and energy efficiency. For example, phenolic foam insulation is recognized by the EPA (Environmental Protection Agency) for its low global warming potential (GWP) and zero ozone depletion potential (ODP). These attributes make phenolic insulation a preferred choice for green building projects and initiatives aimed at reducing environmental impact.

Conclusion: Phenolic Insulation's Environmental Advantages

Lorem ipsum dolor sit amet, The environmental benefits of phenolic insulation, including energy savings, recyclability, and compliance with environmental regulations, underscore its importance in sustainable building construction. By choosing phenolic insulation, builders and architects can create structures that are not only energy-efficient but also environmentally responsible, contributing to a healthier planet for future generations.

Choosing the Right Phenolic Insulation: Factors, Customization, and Quality

Factors to Consider in Selection

When selecting phenolic insulation for a project, several key factors should be considered to ensure optimal performance and sustainability. These factors include the R-value, which measures thermal resistance; the flame spread index, indicating fire safety; and the moisture absorption rate, critical for maintaining indoor air quality. Additionally, the intended application, such as walls, roofs, or piping, will dictate the type and thickness of phenolic insulation needed. By carefully evaluating these factors, builders and architects can choose the most suitable phenolic insulation for their specific requirements.

Customization Options for Specific Projects

Phenolic insulation can be customized to meet the unique needs of various projects. This customization includes different densities, thicknesses, and sizes to fit specific architectural designs and structural requirements. For example, in cold storage facilities, thicker phenolic foam insulation may be used to enhance thermal performance and reduce energy consumption. Similarly, in residential buildings, custom-cut phenolic insulation panels can be designed to fit irregular wall cavities, ensuring a snug fit and maximizing energy efficiency.

Importance of Quality and Certification

The quality and certification of phenolic insulation are crucial for ensuring its performance and sustainability. High-quality phenolic insulation is manufactured to strict standards, ensuring consistent properties such as thermal resistance and fire retardancy. Additionally, certified phenolic insulation products often meet or exceed industry standards, such as those set by the ASTM (American Society for Testing and Materials) and the EPA. Choosing certified phenolic insulation ensures that the material is not only effective but also safe and environmentally friendly, supporting sustainable building practices.

Conclusion: Making Informed Decisions for Sustainable Construction

Selecting the right phenolic insulation involves considering factors such as R-value, flame spread index, and moisture absorption, as well as customization options and quality certifications. By making informed decisions based on these criteria, builders and architects can ensure that their projects benefit from the superior performance and sustainability of phenolic insulation, contributing to the creation of energy-efficient and environmentally responsible buildings.

Conclusion: Durability, Stability, and High-Quality Insulation Solutions

Recap of the Durability and Stability of Phenolic Insulation

Phenolic insulation stands out for its exceptional durability and stability, making it an ideal choice for sustainable building construction. Its resistance to moisture, extreme temperatures, and deformation ensures long-term performance and energy efficiency. With a low thermal conductivity and high compressive strength, phenolic foam insulation provides superior thermal resistance and mechanical stability, supporting the creation of energy-efficient and long-lasting buildings.

The Role of WT in Providing High-Quality Insulation Solutions

WT is a leading manufacturer of phenolic foam insulation, committed to providing high-quality solutions that meet the stringent requirements of modern sustainable construction. The company’s products are designed to enhance energy efficiency and reduce environmental impact, aligning with the principles of green building and sustainable construction practices. WT’s innovative manufacturing processes and rigorous quality control ensure that its phenolic insulation products deliver superior performance and reliability.

Call to Action for Potential Customers and Partners

For builders, architects, and industry professionals seeking to incorporate sustainable and energy-efficient insulation solutions, WT’s phenolic foam insulation offers an excellent choice. Its proven effectiveness in residential, commercial, and industrial applications, combined with its environmental benefits and compliance with industry standards, make it a valuable partner in creating sustainable buildings. We invite potential customers and partners to explore the possibilities of phenolic insulation and join us in advancing the future of sustainable construction.

Conclusion: Embracing Sustainable Building Practices

In conclusion, the durability and stability of phenolic insulation, coupled with WT’s commitment to quality and sustainability, provide a compelling solution for environmentally friendly construction. By choosing phenolic insulation, builders and architects can contribute to the creation of energy-efficient and long-lasting structures, supporting the goals of sustainable building practices and environmental conservation.