Why do some phenolic boards outperform others despite sharing similar certifications? The answer lies in their chemical composition, specifically the structure of their phenol-formaldehyde resins.

With over 50 million square feet installed annually in U.S. construction and HVAC systems, phenolic boards must meet standards like ASTM C1289 and NFPA 285. But beyond compliance, factors such as crosslink density, molecular weight distribution, and residual free formaldehyde directly affect critical properties like Flame Spread Index (ASTM E84), thermal conductivity, and compressive strength.

Industry data shows that up to 65% of material cost differences stem from these formulation variables, impacting both performance and lifecycle costs. For procurement and engineering teams, understanding this chemistry is key to making smarter, value-driven sourcing decisions.

Learn More About: What is Phenolic Insulation?

Chemical Composition of Phenolic Insulation

Phenolic foam boards achieve their high performance through a rigid, closed-cell structure formed by the polymerization of phenol (C₆H₅OH) and formaldehyde (CH₂O). This reaction produces either Resole or Novolac resin systems, each offering distinct material properties.

Resole Resins: Produced under alkaline conditions with excess formaldehyde, these create a highly crosslinked network, delivering superior fire resistance, thermal stability, and lower Flame Spread Index (ASTM E84 ≤ 25)—ideal for high-specification façade and fire-rated applications.

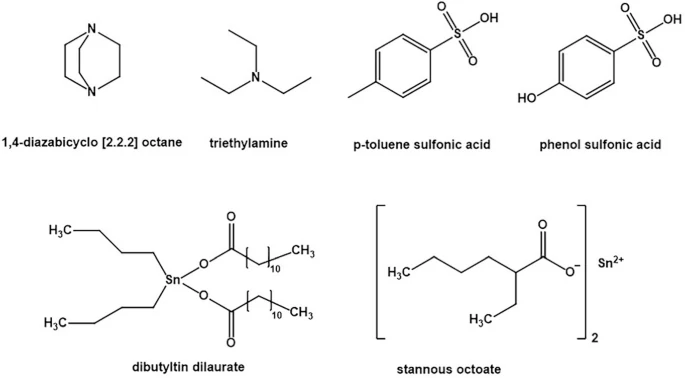

Novolac Resins: Formed under acidic conditions with higher phenol content, Novolac systems require a curing agent and typically provide enhanced mechanical toughness, often preferred for applications demanding higher impact resistance.

The residual free formaldehyde content and crosslink density directly affect the board’s thermal conductivity (λ-value ≤ 0.020 W/m·K), mechanical strength, and long-term durability under heat exposure.

Structural Laminations and Application-Specific Configurations

HVAC Ducting Applications

Typical Laminations: Embossed Aluminum Foil (25–75 microns), Galvanized Steel Sheets, or PVC Films.

Recommended Thickness: 20–50 mm (0.8–2 inches) based on duct size and required thermal performance.

Performance Focus: Lightweight construction, low R-Value loss over time (R-6 to R-7 per inch), and high surface rigidity to withstand handling stress.

Case Example: Aluminum foil facings are ideal for cleanroom HVAC systems where air quality and microbial control are critical.

Exterior Wall Insulation Systems (EWIS)

Typical Laminations: Heavy-duty Aluminum Foil, Colored Steel Sheets (0.4–0.6 mm), or Cement-Coated Fabrics for enhanced weather and impact resistance.

Recommended Thickness: 40–100 mm (1.5–4 inches), achieving total system R-Values from R-6 to R-8 per inch, ideal for energy-efficient building envelopes.

Performance Focus: UV resistance, water vapor barrier efficiency, and compliance with NFPA 285 façade fire performance standards.

Case Example: Cement-coated fabrics are preferred for high-rise façades exposed to severe weather, offering greater impact resistance and long-term durability compared to metal facings.

Manufacturing Process

The performance of phenolic boards is fundamentally determined by the precision of their manufacturing process. High-quality boards begin with carefully controlled synthesis of phenol-formaldehyde resins, typically favoring Resole systems for their superior crosslink density and fire resistance. Poor resin control results in higher Flame Spread Index values and unstable thermal performance.

During foaming, advanced manufacturers use environmentally compliant HFO blowing agents to achieve uniform closed-cell structures, directly improving insulation efficiency. Inconsistent catalyst control at this stage can increase thermal conductivity by up to 15%, reducing overall board performance.

Curing under strictly managed temperatures (150°C to 180°C) ensures complete crosslinking. Insufficient curing leaves residual monomers, weakening structural integrity and increasing off-gassing risks, while over-curing leads to brittleness and early material failure. Improperly cured boards have shown failure rates exceeding 20% within five years, especially in harsh exterior environments.

Final laminations, such as aluminum foil for HVAC or cement-coated fabrics for façades, enhance durability and fire performance. Poor lamination quality often results in delamination under thermal cycling, leading to premature failures.

Boards produced under stringent controls consistently meet critical standards like ASTM E84 and ASTM C518, reducing lifecycle costs by up to 30% through improved durability and performance stability.